Biodegradable PBAT/PLA for Film

HRS-3105 Series Resin is a kind of blending modification material that is based on fully biodegradable polymer. It is does not content any starch or modified starch components. It features in its outstanding physical and mechanical and processing properties which can meet different kinds of film packaging applications.

Product Features:

- 100% biodegradable, can be degraded into water and CO2 within 6 months under industrial compostable conditions. It complies with UN EN 13432 and USA ASTM D6400 standards.

- It can effectively reduce the emission of Petro-based material and CO2 for it composed of highly natural material components.

- It has similar outstanding physical and mechanical properties as conventional PE and PP.

- It can adjust its barrier property and moisture permeability in various applications.

- It broaden processing area with its better forming properties.

- It can be processed quickly in normal conventional extruding equipment.

- It has good dyeing property.

- It features excellent printability and without corona treatment.

- It has good stability of product performance and longer storage lifetime.

- Leftover materials are easy to be recycled.

Servicing and Support:

1、24 hrs technical support.

2、Can provide customized formula according to client’s actual requirement. 3、Can assist for machine commissioning and provide technical guidance on site.

1、201 (HRS-3105-0201)

Main Components:PBAT、PLA、Talc

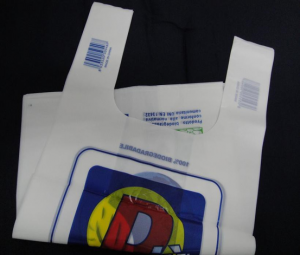

Applications: Fully biodegradable shopping bags, rolling bags, garbage bags, pet fecal bags, clothing package bags, electronic product package bags and food packages and etc.

Physicochemical Property: State: Solid

Color: Light yellow or milk white Odour: almost odourless

Specific Gravity(g/cm3):1.25-1.30 (ASTM D792-2007,23 ℃)

MFR( melt flow rate)(g/10min):2~8 (ASTM D1238-2010,190℃,2.19K) Heat Deflection Temperature <100(℃)(ASTM D648-2007,1.8 Mpa) Tensile Yield Strength(Mpa)≥20(ASTMD 4321-2004,50 mm/min)

Tensile Elongation(%)≥500 (ASTMD 4321-2004,50 mm/min) Heat Sealing Strength:(N/15mm)≥8(ASTM F88-06,300 mm/min)

Right-angled Tearing Strength(N/mm)≥130(ASTM D1004-2009,500 mm/min)

Moisture Content(%)≤0.5 (ASTMD7191-2010)

Degradable Period(D)≤180 (EN13432 &ASTM D6400)

Product Features:

- HRS-3105-0201 resin is 100% biodegradable and compostable, and have passed the attestation for Fully biodegradable Standards of EU EN 13432, USA ASTM 6400 and attestation for Food Contact of SGS.

- Compared with conventional petrochemical plastic resins, HRS-3105-0201 resin can reduce emission of CO2 up to 30% or more.

- HRS-3105-0201 resin does not contain harmful elements such as Pb, Cd, Hg, Cr, PBB, PBDE etc. It is compliant with all requirements under 21CFR177.2600 of U.S. Food and Drug Administration (FDA).

2、101 (HRS-3105-0101)

Main Components:PBAT、PLA

Applications: Fully biodegradable shopping bags, rolling bags, clothing package bags, electronic product package bags and food packages and etc.

Physicochemical Property: State: Solid

Color: Light yellow or milk white Odour: almost odourless

Specific Gravity(g/cm3):1.22~1.25 (ASTM D792-2007,23 ℃)

MFR( melt flow rate)(g/10min):2~8 (ASTM D1238-2010,190℃,2.19K) Heat Deflection Temperature <100(℃)(ASTM D648-2007,1.8 Mpa) Tensile Yield Strength(Mpa)≥25 ASTMD 4321-2004,50 mm/min) Tensile Elongation(%)≥350 ASTMD 4321-2004,50 mm/min)

Heat Sealing Strength(N/15mm)≥12 ASTM F88-06,300 mm/min)

Right-angled Tearing Strength:(N/mm)≥100 ASTM D1004-2009,500 mm/min) Moisture Content(%)≤0.5 (ASTMD7191-2010)

Degradable Period(D)≤180 (EN13432 &ASTM D6400)

Product Features:

- HRS-3105-0101 resin is 100% biodegradable and compostable, and have passed the attestation for Fully biodegradable Standards of EU EN 13432, USA ASTM 6400 and attestation for Food Contact of SGS.

- Compared with conventional petrochemical plastic resins, HRS-3105-0201 resin can reduce emission of CO2 up to 30% or more.

- HRS-3105-0101 resin does not contain harmful elements such as Pb, Cd, Hg, Cr, PBB, PBDE etc. It is compliant with all requirements under 21CFR177.2600 of U.S. Food and Drug

Administration (FDA).

| Comparison | HRS-3105 Series | PBAT+Starch |

| Predrying | No need | Drying for over 4hrs at 90 oC |

| Equipment Requirement | Common LDPE standard specification | Structure to be modified partially of PE blowing machine |

| Output | Fast extruding speed, high output | Low-speed production, more than 30% less output |

| Recoverability of leftover materials | Easy to be recovered, high blend ratio | Hard to recycle, easy to be pasted |

| Power Consumption | Energy-saving, low temperature and high speed, no drying | Need to dry, low speed, high energy consuming |

| Storage Lifetime | Less moisture absorption, long storage time | Easy to absorb moisture and hydrolyze, short storage time |

| Load Bearing Strength | High yield strength and load | Soft, Tensile |

| Soft Hand Feel | Free of Plasticizer, Hard | Contain Plasticizer, Soft |

-

Low Price No Unwanted Smell Acetate Tow With Hi...

-

Perfect Quality Wholesale Plug Wrapping Paper F...

-

Hot Sale 100% Recycled Bleach White A3/A4 Copy...

-

New Design High Quality Cigarette Wrapping Pape...

-

Printable MF Acid Free Tissue Paper Packaging ...

-

Perfect Quality White Cigarette Paper For Wrapp...