In the quest for cleaner air, purer water, and more sterile environments across industries, filtration technology stands as a silent guardian of public health and industrial efficiency. For decades, filtration materials have evolved from basic cloth and paper to sophisticated synthetic polymers. However, a quiet revolution has been underway, fundamentally transforming the capabilities of filters in applications ranging from hospital operating rooms to semiconductor manufacturing cleanrooms, and from the air we breathe in our cars to the water emerging from our taps. At the heart of this revolution lies a seemingly simple material: micro glass fiber.

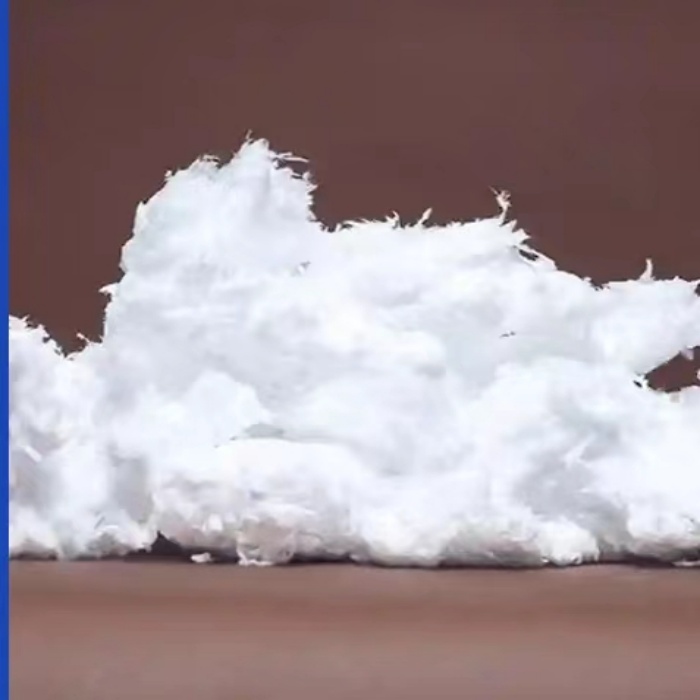

This advanced material, composed of ultrafine fibers typically less than 1 micron in diameter—often down to 0.1 microns or even smaller—is redefining performance standards. Unlike its predecessors, micro glass fiber offers a unique combination of depth filtration, high efficiency, and mechanical robustness that is addressing some of the world’s most pressing filtration challenges. Its adoption is not merely an incremental improvement but a paradigm shift, enabling new levels of purity, safety, and sustainability on a global scale.

The Science Behind the Revolution: Unpacking Micro Glass Fiber

To understand the transformative impact, one must first appreciate the material’s intrinsic properties. Micro glass fibers are produced through a process of controlled melting and fiberization of specialty borosilicate or soda-lime glass. The result is a non-woven mat of randomly oriented, interlocking fibers with several key characteristics:

1. Sub-Micron Geometry: The primary advantage is dimensional. By engineering fibers with diameters smaller than many pollutants—including bacteria (0.2-5 microns), viruses (0.02-0.3 microns), fine dust (PM2.5), and even larger molecules—the material creates an incredibly dense, porous network. This network does not merely act as a sieve at the surface but facilitates depth loading, where particles are trapped throughout the thickness of the medium. This dramatically increases dirt-holding capacity and filter lifespan compared to surface-loading membranes.

2. High Surface Area and Porosity: Despite its density for trapping particles, the material maintains exceptionally high porosity, often exceeding 90%. The labyrinthine web of ultrafine fibers presents an enormous surface area for interaction with contaminants while minimizing resistance to fluid or air flow. This translates to filters that are both highly efficient and energy-efficient, requiring less pumping power or fan energy—a critical consideration for HVAC systems and industrial processes.

3. Inert and Hydrophilic Nature: Glass is inherently inert. It does not off-gas volatile organic compounds (VOCs), absorb moisture, or degrade when exposed to most chemicals, solvents, or extreme pH levels. Furthermore, its naturally hydrophilic (water-attracting) property makes it ideal for liquid filtration without requiring additional wetting agents, ensuring consistent performance in water and fuel filtration from the first use.

4. Thermal and Dimensional Stability: With a melting point often above 500°C, micro glass fiber media can withstand sterilization processes, including autoclaving and exposure to high-temperature exhaust gases. It resists swelling, shrinking, or deforming under varying humidity and temperature conditions, ensuring reliable performance in volatile environments.

Catalyzing Change Across Global Industries

The unique properties of micro glass fiber are catalyzing breakthroughs in diverse sectors, each with its own set of challenges and demands for purity and reliability.

1. Healthcare and Life Sciences: The Frontline of Sterility

The COVID-19 pandemic brutally underscored the importance of air quality in healthcare. High-Efficiency Particulate Air (HEPA) and Ultra-Low Penetration Air (ULPA) filters, which are indispensable in operating theaters, isolation rooms, and pharmaceutical production, rely almost exclusively on micro glass fiber media. These filters achieve 99.97% efficiency (HEPA) or 99.999% efficiency (ULPA) on particles 0.3 microns and larger. This efficacy is crucial for removing airborne pathogens, protecting vulnerable patients, and ensuring sterile conditions for drug manufacturing and biomedical research. Moreover, the material’s compatibility with gamma irradiation and autoclaving allows for the production of sterilizable filter capsules used in critical pharmaceutical fluid processing.

2. Semiconductor and Electronics Manufacturing: Guarding Nano-Scale Precision

In the production of microchips, where a single dust particle can ruin a nanometer-scale circuit, cleanroom air filtration is not an accessory but the foundation of yield. Micro glass fiber ULPA filters provide the ultimate defense against particulate contamination. Their stability ensures they do not shed fibers themselves—a self-defeating problem known as “outgassing” that can plague some polymeric media. This guarantees the integrity of processes worth billions of dollars, enabling the continued miniaturization of electronics.

3. Automotive and Transportation: Enhancing Performance and Protecting Health

Modern vehicles incorporate numerous filters using micro glass fiber media. In cabin air filters, it effectively traps allergens, pollen, and exhaust particulates (PM2.5), significantly improving air quality for occupants. In engine applications, it is used in fuel filters to protect injectors from microscopic contaminants and in lubricating oil filters to extend engine life. The advent of electric vehicles has not diminished its role; rather, it has become critical in filtering coolants and protecting sensitive battery and power electronics systems.

4. Water and Wastewater Treatment: Addressing Scarcity and Pollution

As water scarcity intensifies, advanced filtration for reuse and desalination becomes paramount. Micro glass fiber serves as an excellent pre-filter in reverse osmosis (RO) systems, removing colloidal and particulate matter that would otherwise foul and degrade expensive RO membranes. Its high dirt-holding capacity reduces pre-filter change frequency, lowering operational costs in large-scale desalination and municipal water plants. It is also pivotal in treating industrial wastewater, removing fine suspended solids to meet stringent environmental discharge standards.

5. Energy and Industrial Processes: Enabling Efficiency and Compliance

In the energy sector, gas turbine intake filters made with micro glass fiber protect costly machinery from salt aerosols, dust, and other corrosive particulates in harsh environments, from offshore platforms to deserts. In power generation, baghouse filters equipped with glass fiber media capture fly ash from coal-fired plant emissions. The material’s temperature resistance is key here. Furthermore, as governments worldwide tighten air quality regulations (like the EPA’s NAAQS in the US or the European Green Deal), industries are turning to these high-efficiency media to meet compliance standards for particulate emissions.

The Sustainability and Economic Driver

The revolution is not only technical but also economic and environmental. The longevity of micro glass fiber filters—thanks to depth loading—reduces replacement frequency, lowering long-term costs and waste generation. Their contribution to energy efficiency is substantial; in HVAC systems, which account for nearly half of a commercial building’s energy use, low-resistance, high-efficiency filters reduce the energy burden of moving air, leading to significant carbon footprint reductions over time.

Furthermore, glass is made from abundant silica sand, and while the production is energy-intensive, the material itself is fully recyclable. Research into recycling used filter media into new glass products or construction materials is advancing, promising a move toward a more circular economy for filtration products.

Challenges and the Path Forward

No technology is without its challenges. The handling of raw micro glass fiber requires care due to its potential for irritation during manufacturing, though this is completely mitigated once encapsulated in a filter cartridge. Cost can be higher than some synthetic alternatives, though the total cost of ownership is often lower. The future lies in hybrid approaches, where micro glass fiber is combined with other materials like activated carbon (for chemical adsorption) or nanofiber layers (for enhanced surface filtration) to create multifunctional, next-generation solutions.

Research is also pushing the boundaries of the material itself, exploring even finer nanoscale glass fibers, functional coatings for antimicrobial activity, and improved pleating technologies to pack more surface area into smaller filter housings.

Conclusion: A Foundational Shift

The global adoption of micro glass fiber in filtration represents a foundational shift in our ability to control our environment. It is a material whose time has come, driven by converging trends: heightened health awareness post-pandemic, relentless advancement in high-tech manufacturing, global water crises, stringent environmental regulations, and the universal drive for operational efficiency.

By offering an unmatched combination of efficiency, capacity, stability, and versatility, micro glass fiber has moved from being a component in a filter to being the enabling technology for systems that protect human health, ensure industrial viability, and safeguard our planet. It is, without exaggeration, revolutionizing filtration systems worldwide, providing a clearer, safer, and more sustainable foundation for modern life. As technology and global challenges continue to evolve, this remarkable material will undoubtedly remain at the forefront, filtering our path toward a cleaner future.

Post time: Dec-23-2025