In the specialized and highly competitive world of smokeless tobacco products, the unassuming snus pouch plays a critical role. Snus, a moist powder tobacco product originating from Sweden, has seen its popularity surge globally as consumers seek alternatives to traditional smoking. At the heart of this modern product is the snus paper—the permeable, durable, and tasteless pouch that contains the tobacco. While the tobacco itself is sourced and blended with great care, the manufacturing of the paper pouch is a feat of advanced engineering and precision. In this domain, one nation has emerged as the undisputed global leader: the People’s Republic of China.

China’s dominance in snus paper manufacturing and export is not an accident. It is the result of a powerful convergence of factors: decades of established expertise in paper and non-woven fabrics, unparalleled economies of scale, a relentless drive for technological innovation, and a sophisticated, globally integrated supply chain. This article delves into the core reasons behind China’s premier position in this niche but vital global market.

1. A Legacy of Industrial Prowess: The Foundation in Paper and Non-Wovens

China’s status as the “world’s factory” is well-documented, but its specific leadership in paper and textiles provides the essential bedrock for snus paper production. For generations, China has been a global powerhouse in papermaking, with a deep understanding of pulp processing, fiber technology, and finishing techniques. This historical expertise seamlessly translated into the production of non-woven fabrics—the modern material of choice for high-quality snus pouches.

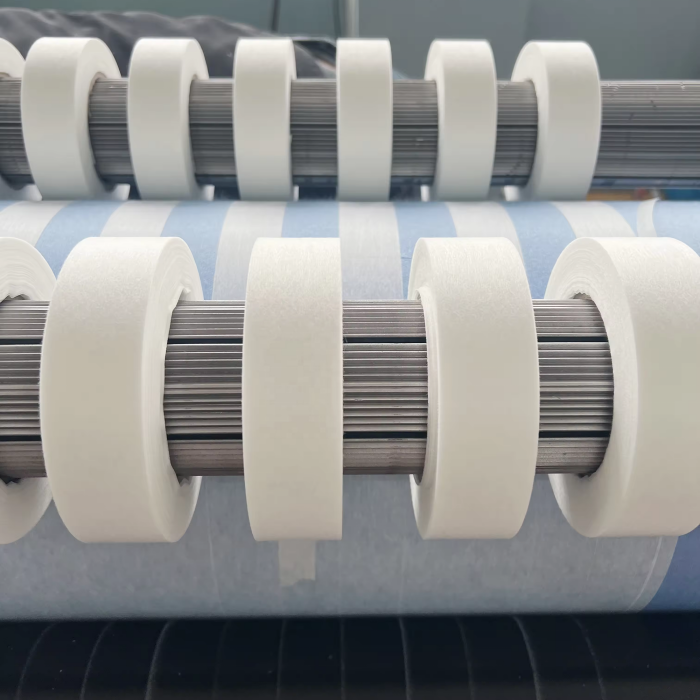

Non-woven fabrics, engineered by bonding fibers together through mechanical, chemical, or thermal processes, offer the perfect combination of strength, porosity, and neutrality required for snus. Chinese manufacturers have mastered the production of these fabrics using premium viscose or other food-grade fibers, ensuring they are:

- Strong yet Soft: The paper must not tear during manufacturing, packaging, or consumer use, yet it must feel comfortable in the mouth.

- Highly Permeable: It must allow for the immediate and consistent release of flavor and nicotine without letting tobacco particles escape.

- Tasteless and Odorless: The material must not impart any papery or chemical taste that could interfere with the carefully crafted tobacco flavors.

This foundational mastery of material science means that Chinese producers aren’t just making paper; they are engineering a sophisticated delivery system to exacting specifications.

2. The Power of Scale and Cost-Efficiency

No other country can match China’s ability to achieve economies of scale in manufacturing. The infrastructure is already in place: vast industrial parks, continuous production lines that operate 24/7, and access to a massive domestic and international logistics network. For global snus brands, which require millions of pouces daily, this scalability is not a luxury—it is a business imperative.

Chinese manufacturers can produce snus paper in colossal volumes at a unit cost that is virtually unmatchable elsewhere. This cost-efficiency stems from several factors:

- Integrated Supply Chains: Many manufacturers control the entire process, from sourcing raw viscose to weaving, finishing, and slitting the paper into rolls ready for filling. This vertical integration eliminates middlemen and reduces costs.

- Advanced Automation: Chinese factories are heavily automated, utilizing state-of-the-art machinery for high-speed production with minimal human intervention, which drastically lowers labor costs per unit.

- Logistical Superiority: With some of the world’s busiest and most efficient ports, such as Shanghai, Ningbo, and Shenzhen, Chinese exporters can ship goods anywhere in the world quickly and reliably, keeping overall supply chain costs low.

This combination allows snus brands to source a critical component at a competitive price, freeing up capital for marketing, R&D, and brand building, thereby fueling their own global expansion.

3. Technological Innovation and R&D Investment

To perceive Chinese manufacturing as solely about low cost is a profound misconception. The country has aggressively moved up the value chain, and its snus paper industry is a prime example. Leading Chinese manufacturers invest heavily in Research and Development (R&D) to stay ahead of market trends and client demands.

This innovation is evident in several areas:

- Customization Capabilities: Chinese firms work closely with snus brands to develop proprietary papers. This can include custom porosity rates for faster or slower flavor release, specific tear strengths, and even the development of eco-friendlier, biodegradable materials in response to growing environmental concerns.

- Precision Engineering: The machinery used to produce and convert the paper is often designed and built in-house or in collaboration with German and Japanese engineering firms. This ensures ultra-precise slitting, sealing, and perforation, resulting in a consistent and high-quality pouch.

- Quality Control and Certification: Top-tier Chinese manufacturers operate under stringent international quality standards, such as ISO and GMP (Good Manufacturing Practice). They employ sophisticated lab equipment to test for everything from tensile strength and permeability to microbiological safety and heavy metal content, guaranteeing a product that is safe, consistent, and reliable.

This commitment to innovation means that global snus brands don’t just come to China for a cheap product; they come for a technologically advanced component that can become a unique selling point for their own products.

4. Agility and Responsiveness in a Dynamic Market

The global tobacco alternatives market is incredibly dynamic, with consumer preferences shifting rapidly. New flavors, nicotine strengths, and product formats (e.g., “all-white” or tobacco-free nicotine pouches) are constantly emerging. Chinese manufacturers have demonstrated a remarkable ability to pivot and adapt to these changes with agility.

Unlike more rigid manufacturing ecosystems, the Chinese industrial landscape is characterized by its flexibility. Factories can quickly retool production lines, experiment with new material blends, and ramp up production of new paper types to meet sudden surges in demand. This “just-in-time” manufacturing philosophy, combined with a deep pool of engineering talent, allows them to be true partners to their global clients, helping them innovate and capture new market opportunities faster than their competitors.

5. A Globalized and Customer-Centric Approach

Finally, China’s leadership is cemented by its outward-looking, customer-centric business ethos. The leading snus paper exporters in China are not isolated entities; they are globally minded corporations with experienced international sales and support teams. They actively participate in global trade shows, engage in technical dialogues with clients in Europe and North America, and provide comprehensive logistical support, including handling complex customs and documentation processes.

They understand the cultural and regulatory nuances of their export markets. For instance, they are adept at navigating the strict regulatory environments of the EU and North America, ensuring their products comply with all relevant food-contact and safety regulations. This professional, service-oriented approach builds long-term trust and strategic partnerships with the world’s leading snus brands.

Conclusion: A Symbiotic Relationship Driving Global Growth

China’s position as the global leader in snus paper manufacturing and export is a multifaceted success story. It is built upon a historical foundation in textiles and paper, supercharged by unparalleled economies of scale, and continuously propelled forward by significant investment in technology and innovation. The agility and customer-focused approach of Chinese manufacturers have made them indispensable partners in the global snus supply chain.

Post time: Nov-13-2025