Industrial insulation is a critical component in various sectors, including manufacturing, petrochemical, power generation, and HVAC systems. The right insulation material can significantly impact energy efficiency, safety, and operational costs. Among the many insulation materials available, micro glass fiber has gained widespread popularity due to its superior thermal performance, durability, and versatility.

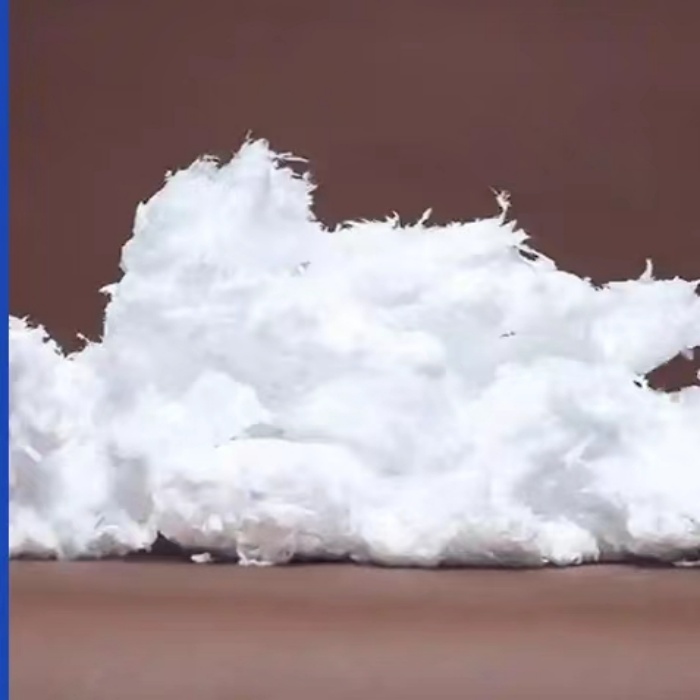

Micro glass fiber insulation is made from extremely fine glass fibers, often with diameters as small as 3 to 5 micrometers. These fibers are woven or compressed into mats, boards, or rolls, providing excellent thermal and acoustic insulation properties. In this article, we will explore the top five benefits of using micro glass fiber in industrial insulation and why it stands out among alternative materials.

1. Exceptional Thermal Performance

One of the primary reasons industries choose micro glass fiber insulation is its outstanding thermal resistance.

Low Thermal Conductivity

Micro glass fiber has a low thermal conductivity (typically between 0.030 and 0.040 W/m·K), meaning it effectively minimizes heat transfer. This property is crucial in industrial settings where maintaining consistent temperatures is essential for both safety and efficiency.

Wide Temperature Range

Unlike some organic insulation materials that degrade at high temperatures, micro glass fiber can withstand extreme temperatures ranging from -260°C to 540°C (-436°F to 1004°F). This makes it suitable for:

- High-temperature pipelines in refineries

- Boilers and steam systems

- Cryogenic applications (e.g., LNG storage)

Energy Efficiency & Cost Savings

By reducing heat loss or gain, micro glass fiber insulation helps industries lower energy consumption, leading to significant cost savings over time. The U.S. Department of Energy estimates that proper insulation can reduce industrial energy costs by up to 20%.

2. Superior Acoustic Insulation

In addition to thermal benefits, micro glass fiber is an excellent sound absorber, making it ideal for noise control in industrial environments.

Noise Reduction Coefficient (NRC)

Micro glass fiber has a high Noise Reduction Coefficient (NRC), often exceeding 0.95 (where 1.0 represents perfect absorption). This makes it effective in:

- Power plants and compressor stations

- HVAC systems

- Manufacturing facilities with heavy machinery

Vibration Damping

The fibrous structure of micro glass insulation also helps dampen vibrations, reducing wear and tear on equipment and improving worker comfort.

3. Fire Resistance & Safety Compliance

Industrial facilities must adhere to strict fire safety regulations, and micro glass fiber insulation meets these requirements with its non-combustible properties.

Non-Combustible Material

Unlike foam or cellulose insulation, micro glass fiber is inorganic and does not burn. It is classified as:

- Class A fire-rated (highest fire resistance)

- Compliant with ASTM E84, UL 723, and EN 13501-1 standards

Toxicity & Smoke Emission

In case of fire, micro glass fiber does not release toxic fumes, making it safer for workers and emergency responders.

4. Durability & Longevity

Industrial insulation must withstand harsh conditions, including moisture, chemicals, and mechanical stress. Micro glass fiber excels in durability and longevity.

Moisture & Mold Resistance

Micro glass fiber is hydrophobic, meaning it repels water and resists mold growth. This is crucial in humid environments or facilities exposed to condensation.

Chemical Resistance

It is also resistant to most acids, alkalis, and solvents, making it ideal for chemical plants and oil refineries.

Compression Resistance

Unlike some insulation materials that degrade under pressure, micro glass fiber maintains its structure even when compressed, ensuring long-term performance.

5. Lightweight & Easy Installation

Finally, micro glass fiber insulation is lightweight and flexible, simplifying installation in complex industrial settings.

Ease of Handling

Compared to rigid insulation boards, micro glass fiber mats and rolls are easier to:

- Cut to size

- Wrap around pipes and ducts

- Install in tight spaces

Reduced Structural Load

Since it is lightweight, it does not add excessive weight to structures, which is beneficial for:

- Offshore platforms

- Aircraft and automotive industries

- Suspended ductwork

Cost-Effective Installation

The flexibility and ease of installation reduce labor costs, making it a cost-effective solution for large-scale projects.

Conclusion

Micro glass fiber insulation offers unmatched thermal efficiency, acoustic control, fire safety, durability, and ease of installation, making it a top choice for industrial applications. Whether for high-temperature processes, noise reduction, or compliance with safety standards, this material provides long-term performance and cost savings.

Industries looking to enhance energy efficiency, improve workplace safety, and reduce operational costs should consider micro glass fiber insulation as a reliable and high-performance solution.

Post time: Jun-26-2025