Micro glass fiber is a high-performance material known for its exceptional strength, thermal resistance, and versatility. With diameters ranging from a few micrometers to sub-micron levels, these fibers are engineered for specialized applications across multiple industries. From filtration and insulation to advanced composites and energy storage, micro glass fibers play a crucial role in modern technology.

As a leading exporter of high-quality micro glass fiber products, we understand the growing demand for this material in global markets. In this article, we will explore the key properties of micro glass fiber and its most important industrial applications.

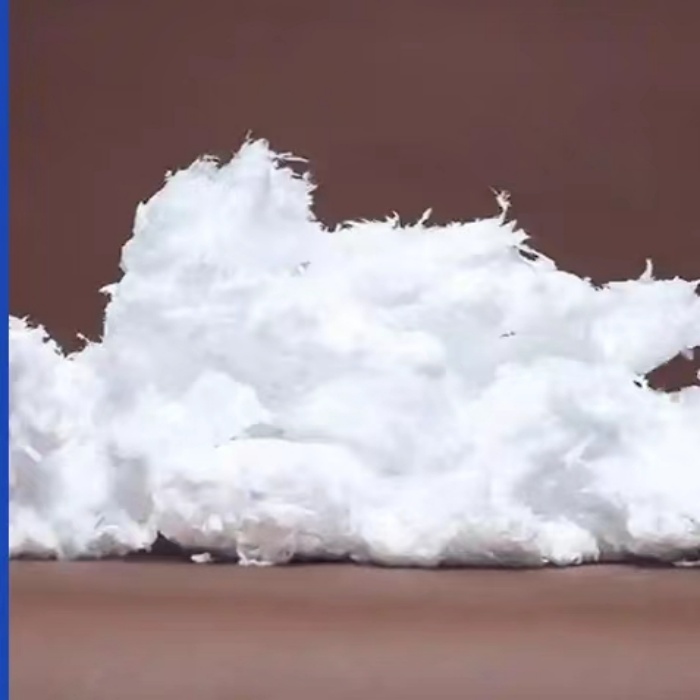

What is Micro Glass Fiber?

Micro glass fiber is made from ultra-fine strands of glass, typically produced through a melt-spinning or centrifugal process. These fibers are lightweight, chemically inert, and exhibit excellent mechanical and thermal properties. Key characteristics include:

- High tensile strength – Resistant to stretching and breaking under stress.

- Thermal stability – Can withstand extreme temperatures (up to 1000°C in some cases).

- Chemical resistance – Non-reactive with most acids, alkalis, and solvents.

- Low thermal conductivity – Ideal for insulation applications.

- Fine filtration capability – Effective at trapping microscopic particles.

These properties make micro glass fiber indispensable in industries requiring durability, efficiency, and precision.

Key Applications of Micro Glass Fiber

1. Filtration Systems

One of the most common uses of micro glass fiber is in air, liquid, and gas filtration. Due to its fine structure, it can capture particles as small as 0.1 microns, making it ideal for:

- HEPA & ULPA filters – Used in hospitals, cleanrooms, and pharmaceuticals to remove airborne contaminants.

- Automotive filters – Improves engine performance by trapping fine dust and pollutants.

- Industrial gas filtration – Removes hazardous particles in chemical processing and power plants.

Compared to synthetic fibers, glass fiber filters offer superior efficiency, longer lifespan, and better resistance to high temperatures.

2. Thermal and Acoustic Insulation

Micro glass fiber is widely used in insulation materials due to its low thermal conductivity and sound-absorbing properties. Applications include:

- Building insulation – Enhances energy efficiency in walls, roofs, and HVAC systems.

- Aerospace & automotive insulation – Protects against extreme heat and reduces noise.

- Industrial equipment insulation – Prevents heat loss in pipelines, boilers, and furnaces.

Its non-combustible nature also makes it a safer alternative to organic insulation materials.

3. Reinforced Composites

In the composites industry, micro glass fiber is used as a reinforcement material to improve strength and durability. Key uses include:

- Fiberglass-reinforced plastics (FRP) – Used in automotive parts, boat hulls, and wind turbine blades.

- Printed circuit boards (PCBs) – Provides structural support and electrical insulation.

- Aerospace components – Reduces weight while maintaining high strength in aircraft structures.

The addition of glass fibers enhances stiffness, impact resistance, and dimensional stability in composite materials.

4. Battery Separators for Energy Storage

With the rise of electric vehicles (EVs) and renewable energy storage, micro glass fiber plays a critical role in battery separators. It is used in:

- Lithium-ion batteries – Prevents short circuits while allowing ion flow.

- Lead-acid batteries – Enhances durability and charge efficiency.

- Fuel cells – Improves performance in hydrogen-based energy systems.

Glass fiber separators offer excellent electrolyte retention and thermal resistance, making them ideal for high-performance batteries.

5. Fireproofing & Protective Textiles

Due to its high melting point and flame resistance, micro glass fiber is used in:

- Fire-resistant clothing – Protects firefighters and industrial workers.

- Fireproof blankets & curtains – Used in buildings and ships to contain flames.

- Thermal barriers – Shields sensitive equipment from extreme heat.

Unlike organic fibers, glass fiber does not burn, making it a reliable safety material.

6. Medical & Biotechnology Applications

In the medical field, micro glass fiber is used in:

- Surgical dressings – Promotes wound healing with minimal irritation.

- Lab filtration – Used in blood tests, sterile filtration, and pharmaceutical processing.

- Biocompatible implants – Research is ongoing for tissue engineering applications.

Its inert nature ensures compatibility with biological tissues.

7. Electronics & Telecommunications

Micro glass fiber supports the electronics industry in:

- Optical fiber cables – Enhances data transmission in telecommunications.

- Insulating materials – Protects circuit boards and electronic components.

- EMI/RFI shielding – Reduces electromagnetic interference in sensitive devices.

Its dielectric properties make it valuable in high-frequency applications.

Why Choose Our Micro Glass Fiber Products?

As a trusted exporter of micro glass fiber, we provide:

✅ High-purity materials – Free from contaminants for critical applications.

✅ Customizable fiber diameters – Tailored to specific industry needs.

✅ Strict quality control – Compliance with international standards (ISO, ASTM).

✅ Global logistics support – Reliable shipping to meet your deadlines.

Whether you need filtration media, insulation, or composite reinforcement, our micro glass fiber solutions deliver unmatched performance.

Conclusion

Micro glass fiber is a multifunctional material driving innovation across industries. From improving air quality with advanced filters to enabling next-gen batteries and lightweight composites, its applications are vast and growing.

As demand for high-performance materials increases, businesses worldwide rely on high-quality micro glass fiber suppliers to meet their technical requirements. If you’re looking for a dependable partner in micro glass fiber exports, contact us today to discuss your needs!

Post time: Jun-26-2025