In the realm of advanced materials, few substances are as versatile and transformative as micro glass fiber. These incredibly fine strands of glass, often thinner than a human hair, are the unsung heroes behind countless innovations that define modern life. From the sleek smartphone in your hand to the energy-efficient insulation in your home, micro glass fibers play a pivotal role.

This ultimate guide delves deep into the world of micro glass fiber, exploring its fundamental properties, vast array of applications, and the significant benefits it offers across industries.

What is Micro Glass Fiber?

Micro glass fiber, also known as glass microfibers or microfiber glass, is a material composed of extremely fine glass filaments. These fibers are typically produced through a process similar to making cotton candy: molten glass is extruded through ultra-fine bushings and rapidly cooled to form continuous filaments with diameters ranging from several micrometers down to sub-micrometer levels (often between 0.5 to 10 µm).

The primary raw material is silica sand, combined with other minerals like limestone, soda ash, and borax. The specific composition can be altered to create different types of glass fibers (e.g., E-glass for electrical insulation, A-glass for alkali resistance, C-glass for chemical corrosion resistance), each tailored for specific performance characteristics.

Key Properties and Characteristics

The extraordinary utility of micro glass fiber stems from its unique combination of physical and chemical properties. These characteristics make it superior to many organic and metallic fibers for specialized applications.

1. Exceptional Strength-to-Weight Ratio

Despite their fragile appearance, individual glass fibers are remarkably strong. The drawing process used in their manufacture aligns the glass molecules, creating a structure with high tensile strength. When bundled into yarns or mats, they form a lightweight yet incredibly robust material.

2. High Thermal Resistance

Glass is inherently non-flammable and can withstand high temperatures without melting (until its melting point, typically above 1000°C) or degrading. This makes micro glass fiber an ideal material for thermal insulation and fire protection applications.

3. Excellent Electrical Insulation

The non-conductive nature of glass makes micro glass fibers a perfect electrical insulator. They are used extensively in the electronics industry to separate conductive components and prevent short circuits.

4. Superior Filtration Efficiency

The fine diameter of the fibers allows for the creation of dense, porous mats with a vast surface area. This structure is highly effective at capturing and retaining microscopic particles, including dust, pathogens, and pollutants, making it a premier filtration media.

5. Chemical Inertness

Most types of glass fibers are resistant to attack by most chemicals, including acids, solvents, and oxidants. This inertness ensures long-term stability and performance in harsh environments, from chemical labs to industrial exhaust systems.

6. Dimensional Stability

Micro glass fibers exhibit minimal expansion or contraction when exposed to changes in temperature and humidity. This dimensional stability is critical for applications like printed circuit boards (PCBs) and composite reinforcements, where even minor warping can be catastrophic.

7. Hydrophilic Nature

Unlike polymer-based microfibers, glass fibers are hydrophilic, meaning they readily absorb water and resins. This property is essential for their use in battery separators and composite materials, where even saturation with a liquid is required.

Diverse Applications Across Industries

The unique properties of micro glass fiber have led to its adoption in a stunning variety of fields. Its application is often a key enabling technology.

1. Filtration

This is one of the largest and most critical applications.

- HVAC Systems: High-efficiency particulate air (HEPA) and ULPA filters rely on micro glass fiber mats to remove over 99.97% of airborne particles, including pollen, mold spores, and bacteria.

- Industrial Processes: They are used to filter hot gases, capture fine particulates from exhaust streams, and purify process liquids in the chemical and pharmaceutical industries.

- Automotive: Cabin air filters and intake air filters use glass fiber media to protect engines and passengers from contaminants.

- Water Purification: Glass fiber filters are used in laboratories and industries to analyze and sterilize water samples.

2. Reinforcement in Composites

Micro glass fibers are a fundamental reinforcement material in composite plastics, creating what is commonly known as fiberglass.

- Automotive: Used to manufacture lightweight, strong, and complex parts like bumpers, body panels, and under-hood components, improving fuel efficiency.

- Aerospace & Marine: Used in boat hulls, kayaks, and aircraft components due to its high strength and corrosion resistance.

- Construction: Used in products like glass-reinforced concrete (GRC) panels and pipes, adding tensile strength and crack resistance.

- Printed Circuit Boards (PCBs): The core substrate of most PCBs is a woven glass fiber fabric (like style 1080 or 2116) impregnated with epoxy resin. This provides the necessary mechanical strength, dimensional stability, and electrical insulation.

- Battery Separators: In lead-acid batteries, micro glass fiber mats are used as separators between positive and negative plates. They absorb the electrolyte and prevent electrical shorting.

- Fiber Optic Cables: While not the core conductor, glass fibers are used in the strength members and protective layers of fiber optic cables.

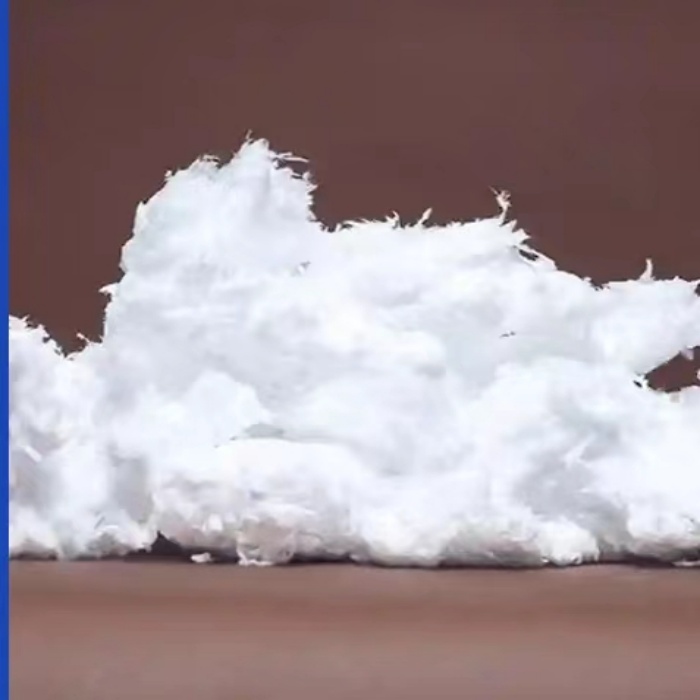

- Building Insulation: Glass wool, a fluffy material made from intertwined glass fibers, is a ubiquitous insulation material in walls, attics, and pipes, significantly improving energy efficiency.

- Appliance Insulation: Used in ovens, refrigerators, and water heaters to contain heat and improve efficiency.

- Acoustic Control: The dense, fibrous mat is excellent at absorbing sound waves, making it useful in studio panels, automotive dashboards, and industrial noise control applications.

- Life Sciences: Used as a substrate in diagnostic test strips and sample collection devices.

- Aerospace: High-purity quartz micro fibers are used in the heat shields of spacecraft due to their exceptional thermal properties.

- Photocopiers and Printers: As a component of the toner, helping to control flow and prevent caking.

3. Electronics and Telecommunications

4. Thermal and Acoustic Insulation

5. Specialty Applications

The Multifaceted Benefits: Why Choose Micro Glass Fiber?

The widespread use of micro glass fiber is not accidental; it is driven by a compelling set of benefits.

- Enhanced Performance: It enables products to perform better—filters capture finer particles, composites are stronger and lighter, and insulation is more effective.

- Durability and Longevity: Products incorporating micro glass fiber are resistant to heat, corrosion, and chemical degradation, leading to a longer service life and reduced maintenance costs.

- Energy Efficiency: By improving thermal insulation in buildings and appliances, micro glass fiber directly contributes to significant energy savings and a reduced carbon footprint.

- Safety: Its non-flammable nature and use in firewalls and protective equipment enhance safety in transportation, construction, and industry.

- Miniaturization: In electronics, the strength and stability of glass fiber substrates allow for the creation of smaller, more complex, and more reliable PCBs, driving the advancement of technology.

- Cost-Effectiveness: Despite its advanced properties, glass fiber is produced from abundant raw materials (sand), making it a relatively low-cost, high-performance material compared to alternatives like carbon fiber.

Conclusion

Micro glass fiber is a foundational material of the modern world. Its unique synergy of strength, thermal resistance, chemical inertness, and filtration capability has made it an indispensable component across a breathtaking spectrum of industries. From protecting our health through advanced filtration to enabling the digital revolution through robust electronics, and from making our vehicles more efficient to keeping our homes comfortable, the impact of these tiny fibers is immense.

As technology continues to advance, pushing the boundaries of material science, the role of micro glass fiber is set to evolve further. Its proven benefits and adaptable nature ensure that it will remain at the forefront of innovation, continuing to provide elegant solutions to complex engineering challenges for years to come. For engineers, designers, and product developers, understanding the properties and potential of micro glass fiber is key to unlocking new possibilities.

Post time: Sep-04-2025