The global tobacco industry continues to thrive, with an increasing demand for high-quality cigarette paper. Whether for traditional cigarettes, roll-your-own (RYO) tobacco, or herbal blends, the right cigarette paper plays a crucial role in smoking experience, burn rate, and overall product quality. For manufacturers and exporters, understanding the key aspects of premium cigarette paper—such as material composition, production standards, and market trends—is essential for success in international trade.

This comprehensive guide explores everything exporters need to know about high-quality cigarette paper, including:

- Types of Cigarette Paper

- Key Features of Premium Cigarette Paper

- Manufacturing Process & Quality Control

- International Standards & Certifications

- Top Export Markets & Trends

- Packaging & Branding Strategies

- Challenges & Solutions in Exporting Cigarette Paper

By the end of this guide, you’ll have a clear understanding of how to produce, market, and export top-tier cigarette paper to global buyers.

1. Types of Cigarette Paper

Cigarette paper varies based on material, thickness, and burn rate. The most common types include:

A. Wood Pulp Paper

- Made from natural wood fibers.

- Affordable and widely used in mass-produced cigarettes.

- May contain additives for better burning.

- Made from flax fibers, offering a smoother burn.

- Preferred for premium and hand-rolled cigarettes.

- Thinner and stronger than wood pulp paper.

- Traditionally used in Asian markets.

- Ultra-thin and slow-burning.

- Often unbleached for a natural look.

- Eco-friendly option gaining popularity.

- Durable and slow-burning.

- Used in specialty and organic tobacco products.

- Made from recycled tobacco byproducts.

- Enhances flavor and reduces waste.

- Common in some European markets.

B. Flax (Linen) Paper

C. Rice Paper

D. Hemp Paper

E. Reconstituted Tobacco Paper

Each type caters to different consumer preferences, so exporters must align their product offerings with market demand.

2. Key Features of Premium Cigarette Paper

To stand out in the export market, cigarette paper must meet high-quality standards. Key features include:

A. Slow & Even Burn

- Prevents “canoeing” (uneven burning).

- Ensures a consistent smoking experience.

- High-quality papers leave fine, white ash.

- Low-quality papers produce dark, flaky ash.

- Should not alter the tobacco’s flavor.

- Chlorine-free and additive-free options are preferred.

- Controls airflow and burn rate.

- Measured in Coresta units (standard for cigarette paper).

- Must be easy to roll but durable enough to handle.

- Flax and hemp papers excel in this aspect.

- Growing demand for sustainable, unbleached, and organic papers.

- Certifications like FSC (Forest Stewardship Council) add value.

B. Minimal Ash Residue

C. Neutral Taste

D. Optimal Porosity

E. Strength & Tear Resistance

F. Eco-Friendliness

3. Manufacturing Process & Quality Control

Producing high-quality cigarette paper requires precision and strict quality control.

A. Raw Material Selection

- Only high-grade wood pulp, flax, or hemp should be used.

- Suppliers must comply with international safety standards.

- Fibers are broken down, refined, and formed into thin sheets.

- Additives (like calcium carbonate) may be included for burn control.

- Sheets are dried uniformly to prevent brittleness.

- Precision cutting ensures consistent size and weight.

- Burn Test: Checks for evenness and speed.

- Porosity Test: Measures air permeability.

- Tensile Strength Test: Ensures durability.

B. Pulp Processing & Sheet Formation

C. Drying & Cutting

D. Quality Testing

Manufacturers must adhere to ISO 9001 and Coresta standards to guarantee export readiness.

4. International Standards & Certifications

Exporting cigarette paper requires compliance with global regulations:

A. Coresta Standards

- Sets guidelines for porosity, burn rate, and ash content.

- Essential for European and North American markets.

- The U.S. (FDA) and EU (TPD) regulate tobacco products.

- Packaging must include health warnings where required.

- Eco-conscious buyers look for sustainably sourced materials.

- Ensures no harmful chemicals are present.

B. FDA & TPD Compliance

C. FSC & Organic Certifications

D. REACH & RoHS Compliance

Meeting these standards enhances credibility and marketability.

5. Top Export Markets & Trends

A. Leading Importers of Cigarette Paper

- Europe (Germany, France, Netherlands) – High demand for flax and eco-friendly papers.

- North America (USA, Canada) – Growing RYO (roll-your-own) market.

- Asia-Pacific (China, Japan, India) – Rice paper and ultra-thin variants dominate.

- Middle East & Africa – Emerging markets with increasing demand.

B. Current Trends

- Organic & Unbleached Papers: Health-conscious consumers prefer natural options.

- Flavored & Pre-Gummed Papers: Convenience-driven innovations.

- Custom Branding: Private-label cigarette papers for tobacco brands.

- Resealable packs for freshness.

- Compact designs for retail appeal.

- Ingredients, burn rate, and certifications should be visible.

- Multilingual packaging for global markets.

- Many distributors seek white-label cigarette paper for branding.

- Solution: Work with legal experts to ensure compliance.

- Solution: Focus on superior quality and eco-friendly options.

- Solution: Use moisture-resistant packaging for long shipments.

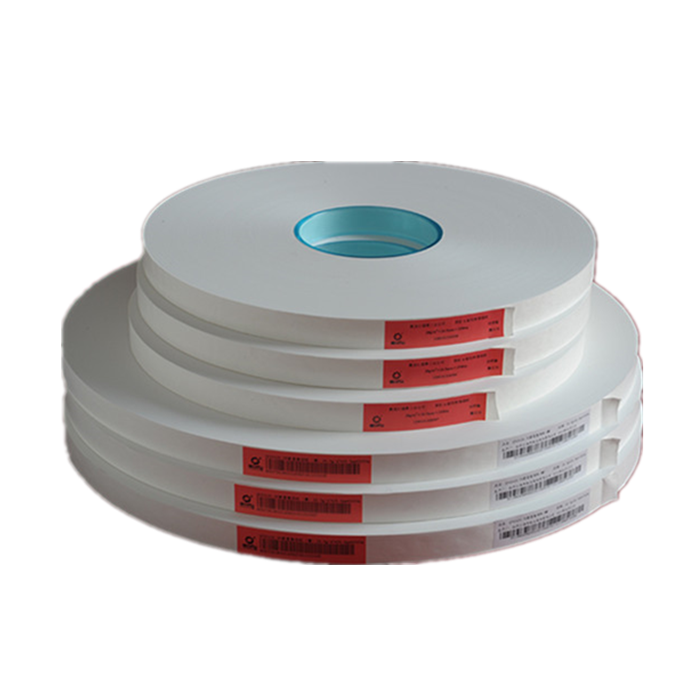

6. Packaging & Branding Strategies

A. Attractive & Functional Packaging

B. Clear Labeling

C. Private Label Opportunities

7. Challenges & Solutions in Exporting Cigarette Paper

A. Regulatory Hurdles

B. Competition from Local Manufacturers

C. Logistics & Shelf Life

Conclusion

Exporting high-quality cigarette paper requires a deep understanding of materials, manufacturing, regulations, and market trends. By focusing on premium materials, strict quality control, and innovative branding, exporters can capture a significant share of the global market.

Whether you’re targeting Europe’s flax paper demand or North America’s RYO trend, this guide provides the foundation for a successful export strategy. Stay ahead by embracing sustainability, technology, and consumer preferences—ensuring long-term growth in the cigarette paper industry.

Post time: Jul-24-2025