Plastic waste has become one of the most pressing environmental challenges of our time. With millions of tons of plastic ending up in landfills and oceans each year, effective recycling methods are crucial for reducing pollution and conserving resources. Among the various types of plastics, polyethylene (PE) is one of the most widely used due to its versatility in packaging, containers, and industrial applications. However, recycling PE efficiently requires advanced separation techniques to ensure high-quality recycled material.

PE separators play a vital role in sustainable plastic recycling by enabling the efficient sorting and purification of polyethylene from mixed plastic waste streams. This article explores the importance of PE separators, their working mechanisms, technological advancements, and their impact on the circular economy.

The Challenge of Plastic Recycling

Plastic recycling faces several challenges, including contamination, mixed polymer streams, and the degradation of material quality during reprocessing. Unlike metals or glass, plastics are composed of different polymer types (e.g., PET, PP, PVC, PE), each requiring separate recycling processes. When different plastics are mixed, the resulting recycled material may have inferior mechanical properties, limiting its usability.

Polyethylene, in particular, is commonly found in packaging films, bottles, and household products. However, if PE is contaminated with other plastics or additives, its recyclability decreases. Therefore, effective separation technologies are essential to ensure that recycled PE meets industry standards for reuse.

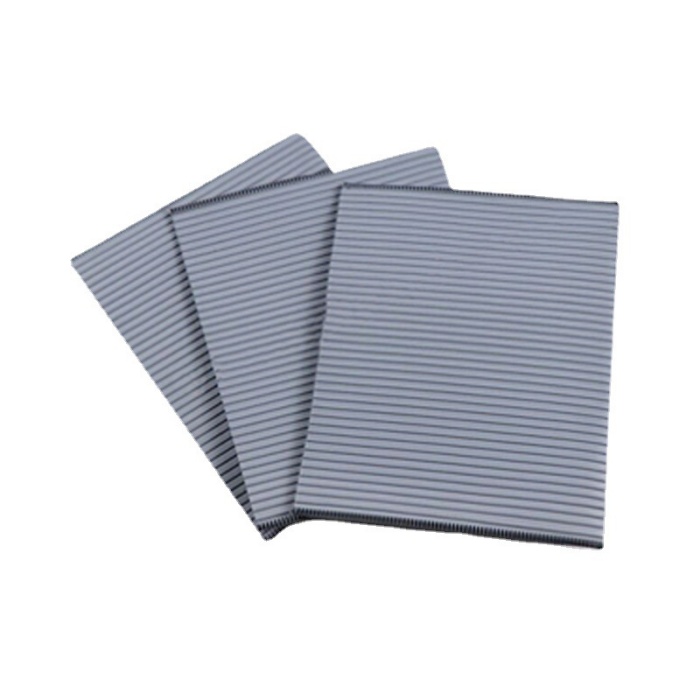

What Are PE Separators?

PE separators are specialized machines or systems designed to isolate polyethylene from mixed plastic waste. These separators utilize various physical and chemical properties of plastics—such as density, electrostatic charge, optical characteristics, and solubility—to achieve high-purity PE separation.

Key Methods of PE Separation

- Density Separation (Sink-Float Method)

- Different plastics have varying densities. By using a liquid medium (often water or a salt solution), lighter plastics like PE (density ~0.92–0.97 g/cm³) float, while denser plastics (e.g., PVC, PET) sink.

- This method is cost-effective but may struggle with similarly dense plastics or contaminated materials.

- Near-Infrared (NIR) Sorting

- NIR spectroscopy identifies polymers based on their unique light absorption patterns.

- Automated sorting systems use NIR sensors to detect and separate PE from other plastics with high accuracy.

- Electrostatic Separation

- Plastics acquire different electrostatic charges when subjected to friction.

- Charged plastics are then separated using an electric field, allowing PE to be isolated from other polymers.

- Dissolution-Precipitation

- Some advanced recycling methods dissolve mixed plastics in solvents that selectively dissolve PE, which is later precipitated out.

- This technique produces high-purity PE but requires chemical handling and solvent recovery.

- Triboelectric Separation

- A newer method where plastics are charged through friction and separated based on their triboelectric properties.

- This approach is energy-efficient and suitable for fine plastic particles.

Advancements in PE Separation Technology

Recent innovations have significantly improved the efficiency and sustainability of PE separators:

- AI and Machine Learning Integration

- Smart sorting systems now use AI to enhance NIR and robotic sorting, increasing accuracy and reducing human error.

- High-Throughput Systems

- Modern PE separators can process thousands of tons of plastic waste per day, making large-scale recycling feasible.

- Chemical Recycling Compatibility

- Some separators are designed to work in tandem with chemical recycling processes, where PE is broken down into monomers for repolymerization.

- Eco-Friendly Solvents

- Green chemistry approaches are being adopted to minimize environmental impact in dissolution-based separation.

The Environmental and Economic Benefits

The use of PE separators in plastic recycling offers multiple advantages:

1. Reducing Landfill Waste

By efficiently extracting PE from mixed waste, separators help divert more plastic from landfills, decreasing environmental pollution.

2. Lowering Carbon Footprint

Recycling PE consumes less energy than producing virgin plastic from fossil fuels, leading to significant CO₂ emission reductions.

3. Promoting a Circular Economy

High-purity recycled PE can be reused in new products, reducing reliance on virgin materials and supporting sustainable manufacturing.

4. Economic Viability

Recycled PE is a valuable commodity in industries such as packaging, construction, and automotive manufacturing, creating economic incentives for recycling businesses.

Challenges and Future Outlook

Despite their benefits, PE separators face some limitations:

- High Initial Costs

- Advanced sorting technologies (e.g., AI-powered NIR systems) require significant investment.

- Contamination Issues

- Food residues, adhesives, and multi-layer plastics can complicate separation processes.

- Policy and Infrastructure Gaps

- Many regions lack the necessary recycling infrastructure to implement large-scale PE separation.

To overcome these challenges, future developments should focus on:

- Scaling up affordable separation technologies

- Improving collection and pre-sorting systems

- Encouraging regulatory support for plastic recycling initiatives

Conclusion

PE separators are indispensable in advancing sustainable plastic recycling. By enabling the efficient recovery of high-quality polyethylene, these technologies help reduce plastic waste, conserve resources, and support a circular economy. Continued innovation in separation methods, combined with stronger recycling policies, will further enhance the role of PE separators in creating a cleaner and more sustainable future.

As industries and governments prioritize plastic waste management, investing in advanced PE separation systems will be key to achieving global sustainability goals. The journey toward a zero-waste future depends on such technological advancements, making PE separators a cornerstone of modern recycling efforts.

Post time: Jul-03-2025