In the relentless pursuit of a sustainable energy future, the spotlight often shines on high-profile components like cathodes, anodes, and electrolytes. However, the silent guardian ensuring the safety, longevity, and performance of every modern battery is the separator. This critical, porous membrane, placed between the positive and negative electrodes, must allow ionic flow while preventing electronic contact. As battery technologies evolve towards higher energy densities, faster charging, and enhanced safety, the materials science behind separators becomes paramount. Among the innovative materials redefining this space, micro glass fiber has emerged as a pivotal player, particularly in specialized and next-generation battery systems, offering a unique combination of properties that polymeric separators alone cannot achieve.

This article delves into the role of micro glass fiber in advancing battery separator technology, exploring its intrinsic properties, applications across various battery chemistries, synergistic uses in composite separators, and its potential in shaping the future of energy storage.

1. Fundamental Properties and Advantages of Micro Glass Fiber

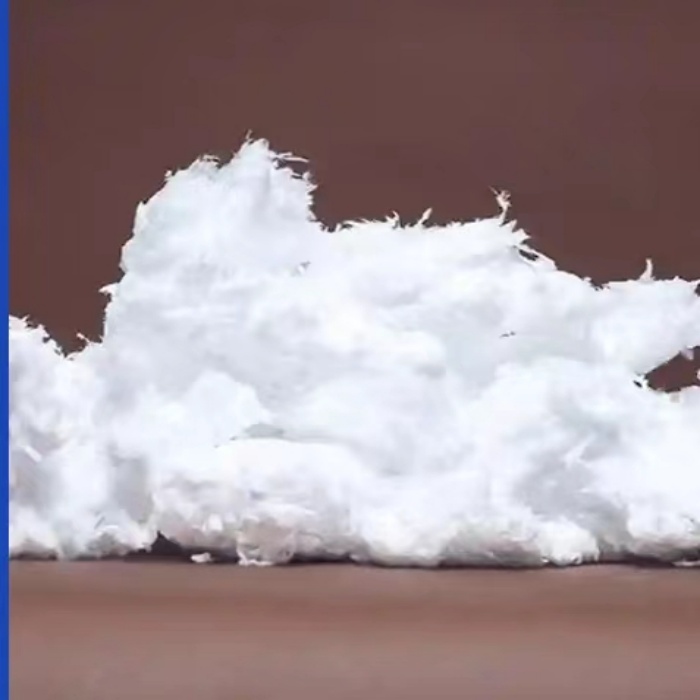

Micro glass fibers are ultra-fine fibers, typically with diameters ranging from sub-micron to a few microns, manufactured from borosilicate or other specialty glasses. Their deployment in separators leverages several inherent advantages:

- Exceptional Thermal Stability: This is arguably its most significant asset. Unlike common polyolefin separators (polyethylene/PP), which melt and shrink at temperatures above 120-160°C, leading to internal short circuits and thermal runaway, glass fibers are thermally inert. They can withstand temperatures exceeding 500°C without melting or losing dimensional integrity. This property is a critical safety firewall in batteries.

- High Porosity and Tunable Pore Structure: The non-woven mats formed from micro glass fibers inherently possess high porosity, often exceeding 80%. This creates low-tortuosity pathways for ions, facilitating high ionic conductivity. Furthermore, the pore size distribution can be engineered during the manufacturing process, allowing for optimization based on the specific electrolyte and active materials used.

- Full Wettability and Electrolyte Uptake: Glass fibers are inherently hydrophilic and exhibit excellent wettability with both aqueous and non-aqueous (organic) liquid electrolytes. This leads to rapid and complete electrolyte saturation, reduced cell assembly time, and more uniform ion distribution. High electrolyte retention also helps maintain performance over extended cycles.

- Chemical and Electrochemical Inertness: High-quality borosilicate glass fibers are highly resistant to corrosion from electrolytes, even under high voltage or strong alkaline/acidic conditions. They do not react with common electrode materials or decompose easily, ensuring long-term stability within the harsh electrochemical environment of a battery.

- Mechanical Strength and Flexibility: While a non-woven glass fiber mat may seem fragile, it exhibits good mechanical strength for handling and winding. When combined with binders or polymeric substrates, it achieves the necessary robustness for automated cell assembly. Its flexibility allows it to be used in various cell formats, including prismatic and pouch cells.

2. Applications in Specific Battery Chemonomies

Micro glass fiber separators are not a one-size-fits-all solution but have found crucial niches where their properties are indispensable.

- Lead-Acid Batteries: This is a traditional and mature application. Absorbent Glass Mat (AGM) separators, composed of micro glass fibers, are the standard in Valve-Regulated Lead-Acid (VRLA) batteries. They immobilize the sulfuric acid electrolyte, enable oxygen recombination (maintaining water balance), and provide the compressible structure needed for plate-group assembly. Their porosity and wettability are key to the high power and maintenance-free operation of AGM batteries used in UPS, automotive start-stop, and renewable energy storage.

- High-Temperature and Specialized Lithium Batteries: In lithium-metal batteries (e.g., Li-SOCl2, Li-MnO2) used in military, medical, and oil/gas downhole applications, operating temperatures can exceed 150°C. Polymeric separators fail here, while micro glass fiber separators provide reliable and safe operation. They are also used in some high-performance lithium primary cells.

- Next-Generation Lithium-Ion and Beyond: While standard liquid-electrolyte lithium-ion batteries predominantly use polyolefin separators, micro glass fiber is making inroads in advanced concepts:

- Solid-State and Semi-Solid Batteries: In emerging solid-state batteries, thin, rigid ceramic separators are common. However, micro glass fiber mats can serve as an excellent porous scaffold or reinforcement layer. They can be infused with polymer or hybrid gel electrolytes, providing mechanical support, preventing dendrite penetration, and maintaining interfacial contact. Their thermal stability aligns perfectly with the safety promise of solid-state technology.

- Lithium-Sulfur (Li-S) Batteries: Li-S batteries suffer from the “polysulfide shuttle,” where soluble polysulfides migrate between electrodes. Micro glass fiber separators, sometimes coated or modified with functional materials, can act as a physical and chemical barrier to trap polysulfides due to their intricate porous network and potential for surface functionalization.

- Aqueous Batteries: For batteries using water-based electrolytes (e.g., Zinc-ion, Nickel-Metal Hydride), the superior wettability and chemical stability of glass fibers offer advantages in rate capability and cycle life.

3. The Composite Approach: Synergy with Polymers and Ceramics

The true advancement often lies in hybridization. Micro glass fiber rarely acts alone in cutting-edge lithium-ion applications but is integrated into composite structures, creating separators with synergistic properties.

- Polymer-Glass Fiber Laminates: A common structure features a thin micro glass fiber layer laminated to one or both sides of a standard polyolefin membrane (e.g., PE or PP). This combines the best of both worlds:Ceramic-Coated Glass Fiber Mats: Micro glass fiber non-wovens can serve as a robust substrate for coatings of nano-ceramic particles (Al2O3, SiO2). This further enhances thermal stability, improves mechanical strength, and can introduce Lewis acid-base interactions to trap harmful species or homogenize lithium-ion flux.

- The polyolefin core provides the essential “shutdown” function (pores close at melt temperature, halting current).

- The glass fiber surface layers dramatically enhance electrolyte wettability and uptake, improve heat resistance at the interface, and add a layer of protection against electrode roughness or dendrite initiation.

- Binder-Integrated Mats: For use as standalone separators, micro glass fibers are often bound together with a small percentage of organic (e.g., acrylic, PVDF) or inorganic binders. This improves mechanical handling properties without significantly compromising porosity or thermal performance.

4. Manufacturing and Sustainability Considerations

The production of micro glass fiber separators involves processes like centrifugation or flame attenuation to create the fine fibers, which are then collected as a wet-laid or dry-laid non-woven mat, followed by curing of binders. While energy-intensive in fiber production, the longevity and safety benefits they impart to batteries can contribute to the overall lifecycle sustainability of the energy storage system. Research is ongoing into more energy-efficient fiber production and the use of recycled glass content. Furthermore, their inorganic nature offers distinct advantages in end-of-life recycling compared to some complex polymer composites.

5. Challenges and Future Perspectives

Despite its advantages, micro glass fiber faces challenges. Its higher cost compared to mass-produced polyolefin separators limits its use to premium or specialty applications. The inherent thickness of a robust glass fiber mat (often >100µm) is a drawback for high-energy-density designs where every micron counts, though ongoing research is producing thinner, stronger mats. Additionally, while flexible, pure glass fiber mats can be more brittle than polymers under extreme bending.

The future of micro glass fiber in battery separators is bright and intertwined with the evolution of battery chemistry:

- Enabler for Solid-State Batteries: As the premier porous, thermally stable scaffold, it is poised to play a central role in hybrid and composite solid electrolyte membranes.

- Safety-First Designs: For electric vehicle and grid storage batteries, where safety is non-negotiable, glass fiber-reinforced or coated separators will see increased adoption as a critical component of multi-layered safety architectures.

- Functionalized Separators: The large surface area of glass fibers provides a perfect platform for anchoring functional nanoparticles or polymers that can catalytically decompose electrolytes, trap impurities, or regulate cation transport, moving the separator from a passive component to an active one.

- Advanced Cell Designs: Its excellent wettability makes it ideal for new electrolyte systems, including highly concentrated and ionic liquid electrolytes, which are often viscous and poorly absorbed by polyolefins.

Conclusion

Micro glass fiber is far more than a legacy material for lead-acid batteries. It represents a sophisticated materials solution addressing the most pressing challenges in modern battery technology: safety at high temperatures, interfacial stability, and compatibility with advanced electrolytes. By offering an unmatched combination of thermal resilience, wettability, and chemical inertness, it advances separator technology beyond the limitations of conventional polymers. Whether as a standalone separator in harsh environments, a key reinforcement in composite solid electrolytes, or a functionalizing substrate in next-generation lithium-metal and lithium-sulfur systems, micro glass fiber is proving to be an indispensable material in the engineering toolkit for building safer, more robust, and higher-performing batteries. As the energy storage landscape marches towards greater demands, the role of this versatile material will only become more profound, solidifying its position as a critical enabler of the electrochemical future.

Post time: Dec-23-2025