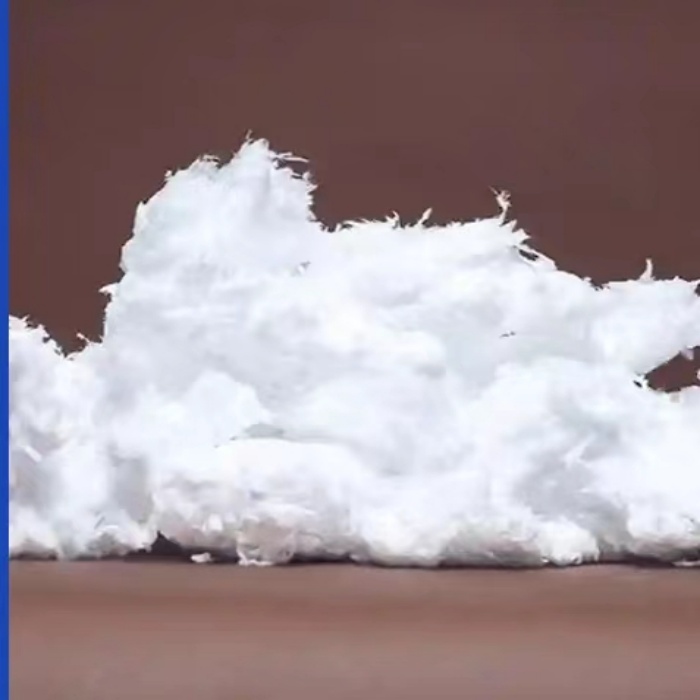

In the intricate world of advanced materials, few components are as deceptively simple yet critically important as micro glass fiber. These tiny, engineered strands of glass are the unsung heroes in a vast array of high-stakes applications, from the circuit boards in your smartphone and the filters in your car to the battery separators powering the electric vehicle revolution. They provide reinforcement, filtration, insulation, and durability where it matters most.

However, not all glass fibers are created equal. The difference between a generic fiber and a high-performance micro glass fiber can be the difference between a product that leads the market and one that fails prematurely. Sourcing the right fiber is not a mere procurement task; it is a strategic decision that impacts product performance, regulatory compliance, supply chain resilience, and ultimately, your bottom line.

This guide will navigate the complexities of sourcing high-performance micro glass fiber, providing a framework to ensure you secure a material that meets your most demanding specifications.

Understanding the Anatomy of Performance: Key Properties to Specify

Before engaging with suppliers, you must first intimately understand your application’s requirements. High-performance is a relative term, defined by the specific demands of your industry. The following properties are the critical levers of performance:

1. Fiber Diameter and Distribution:

This is often the most critical specification. Diameter is typically measured in microns (µm) and directly influences properties like surface area, flexibility, and packing density.

- Fine Fibers (e.g., < 3 µm): Offer high surface area, excellent filtration efficiency for small particles, and form a denser matrix. Ideal for HEPA/ULPA filters, battery separators, and fine filtration.

- Coarser Fibers (e.g., > 6 µm): Provide higher stiffness, better drainage, and are often used for reinforcement in composites and construction materials.

A tight diameter distribution is a hallmark of quality, ensuring consistent and predictable behavior in your process.

2. Chemistry and Composition:

The type of glass used determines its chemical resistance, electrical properties, and thermal stability.

- E-Glass (Electrical Grade): The most common type. Offers excellent electrical insulation, high strength, and good moisture resistance. The standard for PCB substrates, electrical insulation, and many composites.

- C-Glass (Chemical Grade): Formulated for superior resistance to acid corrosion. Essential for chemical filtration media, battery separators, and acid-handling equipment.

- S-Glass (High-Strength): Offers significantly higher tensile strength and modulus than E-glass. Used in aerospace, defense, and high-performance sporting goods where weight and strength are paramount.

- E-CR Glass (Corrosion Resistant): An advanced E-glass variant with improved acid and corrosion resistance without the cost of C-glass.

3. Length and Aspect Ratio:

The length of the fiber influences how it integrates into a matrix.

- Short Mill Fibers: Provide isotropic reinforcement, meaning they strengthen the material evenly in all directions. Used in plastics, rubber, and coatings.

- Continuous Filaments: Provide extremely high, unidirectional strength. Used in woven fabrics for composites, aerospace, and wind turbine blades.

4. Surface Treatment and Sizing:

This is arguably the most crucial “secret sauce” from suppliers. The pristine glass fiber surface is often treated with a chemical coating called a “size” or “coupling agent.”

- Function: The sizing is engineered to chemically bridge the inorganic glass surface with an organic polymer matrix (e.g., epoxy, polyester, polypropylene). A proper sizing ensures optimal wet-out, adhesion, and stress transfer from the matrix to the fiber.

- Importance: An incorrect or low-quality sizing will lead to poor interfacial adhesion, drastically reducing the composite’s mechanical properties and long-term durability. This must be tailored to your specific resin system.

The Strategic Sourcing Process: A Step-by-Step Framework

Step 1: Internal Specification and Cross-Functional Alignment

Begin with a rigorous internal needs assessment. Engage R&D, production, quality assurance, and procurement teams to define:

- Technical Specifications: The non-negotiable minimums for diameter, chemistry, length, and surface treatment.

- Performance Requirements: How the fiber must perform in the final product (e.g., tensile strength, dielectric constant, filtration efficiency).

- Process Compatibility: How the fiber will behave in your manufacturing process (e.g., flowability, resin compatibility, dusting).

- Regulatory Compliance: Necessary certifications (e.g., ISO 9001, IATF 16949, USP Class VI, REACH, RoHS).

Step 2: Supplier Identification and Pre-Qualification

Move beyond simple online directories. Look for established manufacturers with a proven track record in your target industry.

- Reputation and Experience: Do they supply to other top-tier companies in your field? Do they have case studies or white papers?

- Manufacturing Capability: Do they control the entire process from glass melting and fiberization to sizing application? Vertical integration is a strong indicator of quality control.

- R&D Investment: A supplier with a strong R&D department is a partner, not just a vendor. They can help solve problems and innovate for next-generation products.

Step 3: The Technical Dialogue and Sample Evaluation

This is where theory meets reality. Engage potential suppliers in a deep technical discussion.

- Request Detailed Data: Ask for comprehensive Technical Data Sheets (TDS) and Material Safety Data Sheets (MSDS). Request lot-specific Certificate of Analysis (CoA) documents to understand their quality control consistency.

- Insist on Sampling: Never skip this step. Obtain samples from at least two or three short-listed suppliers.

- Rigorous Testing: Put the samples through their paces in your lab. Test them not just for basic properties, but in a formulation or process that mimics your actual production environment. This is the only way to truly assess performance, especially the effectiveness of the surface treatment.

Step 4: Assessing Quality Systems and Supply Chain Reliability

A perfect sample is meaningless if it cannot be consistently reproduced and delivered.

- Quality Certifications: Require proof of robust quality management systems (ISO 9001 is a baseline).

- Audit Potential: Are they open to a customer audit? The willingness to have their facilities and processes inspected is a sign of a confident, transparent supplier.

- Supply Chain Stability: Inquire about their raw material sources, energy security, and contingency plans. The recent global supply chain crises have highlighted the importance of resilience.

Step 5: Total Cost of Ownership (TCO) Analysis

The cheapest fiber per kilogram is almost never the most cost-effective choice.

- Consider: Rejection rates, process efficiency (e.g., less downtime, faster cycle times), enhanced final product performance (allowing you to command a higher price), and longevity.

- A slightly more expensive fiber that improves your yield by 2% or allows you to use 5% less material will pay for itself many times over.

- Electronics & PCB: Prioritize E-glass with extremely low dielectric constants (Dk) and loss tangents (Df). Dimensional stability and CTE (Coefficient of Thermal Expansion) are critical. Traceability and ultra-high purity are mandatory.

- Filtration: Focus on diameter distribution and surface area. For high-efficiency filters, a bimodal distribution (mixing fine and coarse fibers) may be optimal. Chemical resistance (C-glass or E-CR) is vital for harsh environments.

- Transportation & Composites: The interface is everything. The sizing must be perfectly matched to the resin (epoxy, polyamide, etc.). Consistency in diameter and length is key to predictable mechanical properties (strength, stiffness, impact resistance).

- Battery Technology: For separators, fibers must exhibit excellent electrolyte wettability, chemical resistance (to acidic environments), and consistent porosity. Any contamination or inconsistency can lead to short circuits or thermal runaway.

Industry-Specific Sourcing Considerations

Conclusion: From Vendor to Value-Added Partner

Sourcing high-performance micro glass fiber is a complex, technical endeavor that demands a strategic approach. By moving beyond price-based procurement and focusing on a thorough, specification-driven process, you unlock significant value.

The goal is to transition your fiber supplier from a simple vendor to a value-added partner. The right partner will not only deliver a consistent, high-quality product but will also collaborate with your R&D team to pioneer new solutions, help you troubleshoot production challenges, and provide the technical support necessary to maintain a competitive edge.

In the modern industrial landscape, quality isn’t just a metric—it’s your market advantage. Investing the time and resources to source the right micro glass fiber is an investment in the performance, reliability, and success of your products.

Post time: Sep-04-2025