Like other industries in India, the Indian paper industry has also been struggling in the past year. The demand for writing and printing paper has been seriously affected by the continued closure of educational institutions and office space.

Recently, asmehta, chairman and general manager of JK paper industry, President of Indian Paper Manufacturers Association, told the media that at present, the Indian paper industry is actively fulfilling its responsibilities as a basic service department, earnestly restoring the previously interrupted supply chain and striving to restore supply for all walks of life.

Paper industry is an important part of Indian manufacturing industry and one of the oldest industries. The estimated turnover of the industry is 700 billion rupees (domestic market size: 800 billion rupees), and its contribution to finance is about 50 billion rupees (Note: the exchange rate between rupee and RMB is about 1 Indian Rupee ≈ 0.087 yuan). The industry directly provides employment opportunities for 500000 people and indirect employment opportunities for about 1.5 million people.

The industry supports three important national goals: Education for all, green India and rural employment. At present, more than 1.2 million hectares of severely degraded land in rural India are included in pulp plantations to support greening, create rural livelihoods and increase farmers’ income.

In the past few years, Indian paper industry has stepped into the curve of sustainable development and is more advanced in technology. In the past three years, the Indian paper industry has carried out pioneering work in seedling planting. The newly developed seedlings have disease resistance and drought resistance, and can grow under various agroclimatic conditions.

However, there are challenges in India’s paper industry. India is a country short of fiber – the lack of domestic raw material supply is the main restrictive factor for the development of its paper industry.

According to the free trade agreement (FTA), the export of paper to India implements the zero tariff policy, which is extremely unfavorable to the development of the industry. Over the past few years, the Indian paper industry has made a significant leap in technology upgrading, process optimization and the introduction of best practices. Over the past 5-7 years, more than rs. 250 billion has been invested in the introduction of efficient production capacity and green and clean technologies. Over the past five years, the energy consumption of India’s paper industry has decreased by about 20%. Integrated paper mills in India convert more than 40% of their electricity by using biomass from the pulping process. A few years ago, the industry needed 200 cubic meters of water to produce a ton of paper. Now, the comprehensive factory has reduced it to less than 50 cubic meters.

Asmehta believes that the sentence “save paper and protect the environment” has improper semantics. Despite the false propaganda of vested interests, few industries in India can be compared with the sustainability provided by paper. Paper is fully biodegradable and recyclable, and raw materials are renewable and sustainable.

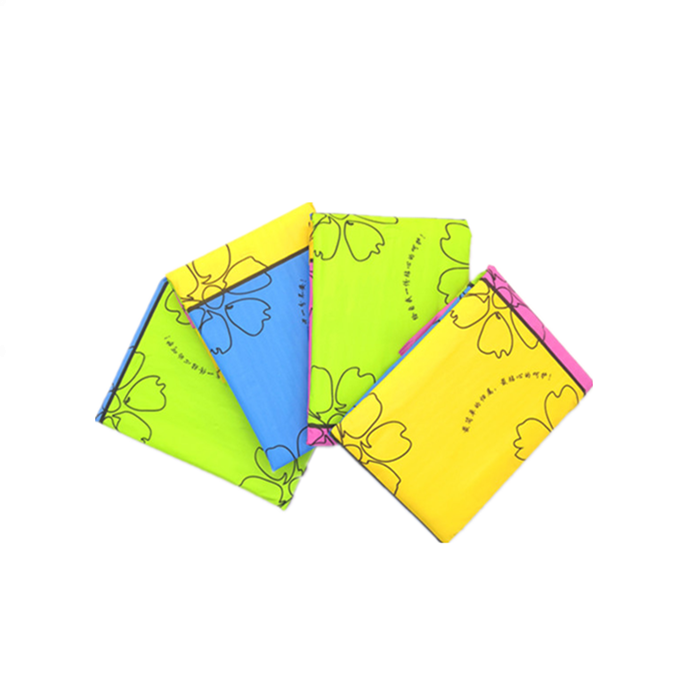

Unlike many industries, this industry not only protects the environment, but also regenerates natural resources. It recycles most of the waste paper and the agricultural waste originally burned in the field. The use of paper has greatly reduced e-waste and disposable plastics, the two most important global environmental problems. It can be said that the paper industry has achieved a good balance between growth and sustainability. Innovation is becoming a new frontier in the paper industry. Various forms of multifunctional paper are also giving more possibilities to modern life.

Post time: Aug-03-2021