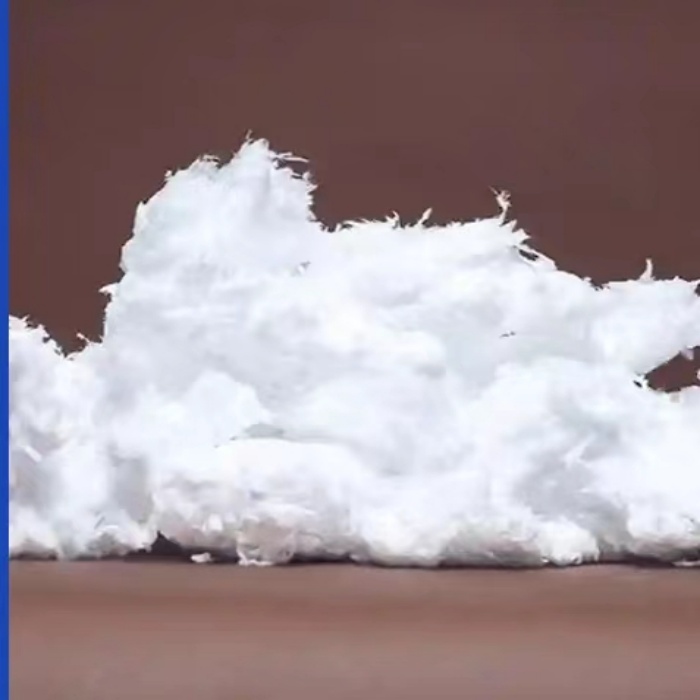

In the ever-evolving world of battery technology, the need for high-performance materials has never been greater. Among these materials, microglass fibers have become the preferred choice for AGM (absorbent glass mat) battery separators. This innovative material offers exceptional properties, including good mildew resistance, excellent high temperature resistance, and superior performance. As the industry continues to pursue improvements in battery efficiency and lifespan, microglass fibers have become a key component in the development of AGM battery separators.

Microglass fibers are known for their unique structural properties, which significantly improve the performance of AGM batteries. The fine fibers form a highly porous matrix that enables optimal electrolyte absorption, ensuring the battery operates efficiently. This property is particularly important for AGM batteries that rely on electrolyte absorption to work effectively. The use of microglass fibers not only improves battery performance, but also extends its service life, making it a valuable asset in a variety of applications ranging from automotive to renewable energy storage.

One of the outstanding properties of microglass fibers is their good resistance to mold. In humid environments, traditional materials may breed mold and compromise the integrity of the battery. However, the inherent resistance to biological threats of microglass fibers ensures that AGM batteries can maintain their performance and reliability for a long time. This feature is particularly important for applications in high humidity areas or batteries stored for long periods of time, as it can reduce the risk of performance degradation due to mold.

High temperature resistance is another key property of microglass fibers, which enhances their suitability as separators for AGM batteries. AGM batteries typically operate over a wide temperature range, and the materials they are made of must be able to withstand these temperature fluctuations without performance degradation. Microglass fibers have excellent thermal stability, maintaining their structural integrity and performance characteristics even in extreme temperature conditions. This toughness not only helps improve the overall reliability of AGM batteries, but also ensures that they perform at their best in a variety of environmental conditions, from extremely hot to extremely cold.

All in all, the incorporation of microglass fibers into AGM battery separator technology represents a significant advancement in the energy storage space. Its unique properties, including good mildew resistance, excellent high temperature resistance, and superior performance, make it ideal for increasing the efficiency and life of AGM batteries. As the demand for reliable, high-performance batteries continues to grow, the role of microglass fibers will undoubtedly become increasingly important, paving the way for innovations that meet the challenges of modern energy storage needs. The future of battery technology is bright, and microglass fibers will lead the way to more durable and efficient AGM batteries.

Post time: May-08-2025