The world of advanced materials is constantly evolving, and at the forefront of this revolution is a component so fine it’s often invisible to the naked eye, yet so powerful it’s reshaping entire industries: the micro glass fiber. For decades, these fibers have been the unsung heroes in applications from thermal insulation to filtration. However, recent breakthroughs in their production, composition, and application are pushing the boundaries of what’s possible, creating unprecedented opportunities for manufacturers to innovate, differentiate, and dominate their markets.

For forward-thinking manufacturers, understanding these innovations is no longer a niche interest—it’s a strategic imperative. This article delves into the key advancements in micro glass fiber technology and explores what they mean for your products, processes, and future roadmap.

The Foundation: What Are Micro Glass Fibers?

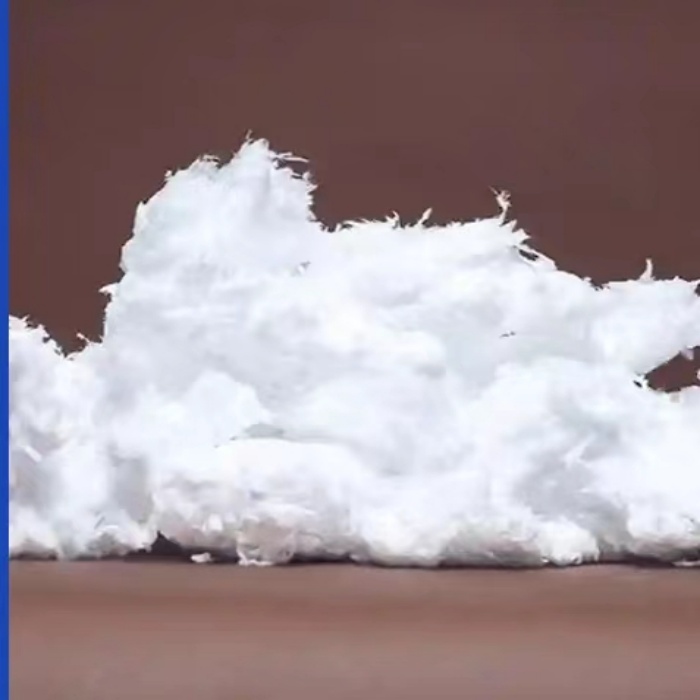

Micro glass fibers are precisely what the name implies: extremely fine strands of glass, typically with diameters ranging from several hundred micrometers down to sub-micron levels—thinner than a human hair. They are produced through a process of melting ultra-pure raw materials (like silica sand, limestone, and soda ash) and then fiberizing the molten glass through centrifugal force, blowing, or drawing.

Their inherent properties make them exceptional:

- High Strength-to-Weight Ratio: Incredibly strong for their size.

- Thermal Stability: Resistant to high temperatures and non-flammable.

- Chemical Inertness: Resistant to most chemicals, preventing corrosion and degradation.

- Dimensional Stability: Minimal expansion or contraction with temperature changes.

- Versatile Formability: Can be produced as loose wool, mats, papers, or woven fabrics.

It is upon this strong foundation that recent innovations are being built.

Key Innovations Reshaping the Landscape

1. Advanced Composition and Surface Modification

The most significant leaps are happening at the molecular and surface levels. Rather than using standard E-glass, manufacturers are now engineering fibers with bespoke compositions.

- High-Purity Silica and Quartz Fibers: These fibers offer exceptional thermal performance, capable of withstanding continuous temperatures over 1000°C. This is critical for aerospace, jet engine insulation, and high-temperature industrial filtration.

- Low Bio-Persistence Fibers: A major driver of innovation has been the health and safety aspect. New alkaline earth silicate (AES) wool compositions are designed to be more soluble in lung fluid than traditional fibers, addressing regulatory concerns and opening doors to new applications with stricter safety protocols without sacrificing performance.

- Functionalized Surfaces: Through plasma treatment, chemical vapor deposition, or the application of specialized sizings, the surface of micro glass fibers can be permanently altered. This allows manufacturers to create fibers that are:

- Hydrophobic or Oleophobic: Repel water or oil, perfect for coalescing filters in aviation fuel or compressed air systems.

- Antimicrobial: Treated with silver ions or other agents to inhibit bacterial growth in HVAC filters or medical applications.

- Enhanced for Composite Bonding: Surface treatments that drastically improve adhesion to polymer matrices in fiber-reinforced composites (GFRP), leading to stronger, more durable parts.

2. Nanofiber Hybridization and Electrospinning

While microfibers form the structural backbone of many materials, integrating nanofibers (fibers with diameters < 1 micron) has become a game-changer, primarily through the process of electrospinning.

- The Concept: A ultra-fine web of polymer nanofibers (e.g., PVDF, Nylon) is directly spun onto a microglass substrate. This creates a multi-layer, hierarchical structure.

- The Manufacturing Benefit: This combination delivers the best of both worlds. The microglass substrate provides mechanical strength, depth filtration, and stability, while the nanofiber layer provides an extremely fine, porous surface that dramatically enhances filtration efficiency for sub-micron particles.

- Impact: This innovation allows filter manufacturers to achieve HEPA/ULPA-level efficiencies with lower pressure drop and longer service life compared to traditional designs. This translates into energy savings for end-users and a superior product offering.

3. Precision in Diameter and Morphology

Not all fibers are created equal. Advanced manufacturing control now allows for unprecedented precision in fiber production.

- Diametric Gradation: Manufacturers can now produce media with carefully engineered gradients of fiber diameter. A filter, for instance, can be designed with coarser fibers on the intake side to capture larger particles and load more dust, and progressively finer fibers on the exit side to achieve high efficiency. This optimizes capacity, efficiency, and energy consumption simultaneously.

- Non-Circular Fiber Cross-Sections: Moving beyond round fibers, new shapes like trilobal or flat fibers are being produced. These shapes increase the surface area within a given volume of material. For filtration, this means more opportunities for particles to be captured. In composites, it enhances the interfacial area for bonding with resins.

4. Smart Manufacturing and Industry 4.0 Integration

The production of micro glass fibers themselves is becoming smarter. IoT sensors, AI, and machine learning are being integrated into the melting, fiberizing, and curing processes.

- Predictive Maintenance: Sensors monitor furnace conditions, fiberizing spinner RPM, and temperatures, predicting maintenance needs before a costly failure occurs, ensuring consistent quality and output.

- Real-Time Quality Control: High-resolution cameras and laser scanners continuously monitor the primary and blanket fibers for defects, diameter consistency, and formation. AI algorithms can make micro-adjustments to the process in real-time, eliminating batch-to-batch variation.

- Customization at Scale: This level of control means manufacturers can produce smaller, highly customized batches of specialty fibers economically, moving away from a one-size-fits-all model.

What Manufacturers Need to Know: Implications and Applications

Understanding these innovations is one thing; applying them is another. Here’s how they translate into tangible benefits across key sectors.

For Filter Manufacturers:

- Opportunity: Develop next-generation filters that offer a clear performance advantage. Use nanofiber hybridization to market filters that save energy. Use functionalized surfaces to create specialized filters for critical environments (labs, hospitals, food production).

- Consideration: Your manufacturing equipment may need to adapt to handle and process these new advanced media effectively. Partnering closely with your material supplier is key.

For Composite Material Producers:

- Opportunity: Create stronger, lighter, and more durable composite parts. Leverage fibers with enhanced sizings for superior resin bonding. Explore non-woven mats made from new fiber compositions for high-temperature pre-pregs.

- Consideration: Test and validate new fiber types thoroughly. The processing parameters (e.g., cure cycle, resin viscosity) may need optimization for the new fiber-matrix interface.

For Battery and Energy Storage Engineers:

- Opportunity: This is a massive growth area. Micro glass fiber separators in lead-acid and lithium-ion batteries are crucial. Innovations in thinness, porosity, and electrolyte wettability directly translate to higher energy density, faster charging, and longer battery life.

- Consideration: Work with fiber producers who understand electrochemistry to co-develop separator solutions tailored to your specific battery chemistry.

For Acoustic and Thermal Insulation Specialists:

- Opportunity: Develop lighter and more efficient insulation products. Low bio-persistence fibers allow you to access new markets in commercial construction and appliance manufacturing where material safety is paramount.

- Consideration: Density and loft management are critical. New fiber compositions may have different acoustical damping properties that need to be characterized.

The Road Ahead: Strategic Partnering is Key

The era of simply buying “fiberglass mat” off the shelf is over. The innovations in micro glass fiber technology are creating a new paradigm where the material is a highly engineered, functional component integral to the final product’s performance.

Therefore, the most critical takeaway for manufacturers is this: shift your relationship with material suppliers from a transactional vendor to a strategic innovation partner.

Engage with suppliers who have R&D capabilities. Discuss your application challenges openly. Inquire about their work in nano-hybridization, surface modification, and specialized compositions. Co-development is the path to creating truly disruptive products that stand out in a competitive global market.

Conclusion

Micro glass fiber technology has entered a new golden age of innovation. Driven by advancements in chemistry, process technology, and digitalization, these tiny fibers are enabling giant leaps in performance across a vast spectrum of industries. For manufacturers, ignoring these trends means risking obsolescence. Embracing them, however, opens a world of possibility—to create products that are more efficient, more sustainable, safer, and smarter than ever before. The future is being built, one fiber at a time, and it’s time to weave these innovations into the fabric of your manufacturing strategy.

Post time: Sep-04-2025