In the sophisticated world of composite materials, every component matters. From the resin matrix that binds everything together to the primary reinforcement that provides bulk strength, each element plays a critical role in determining the final properties of the finished part. Often operating behind the scenes, yet indispensable, are micro glass fibers. These finely milled, high-performance additives are the unsung heroes that elevate a composite from good to exceptional, addressing key challenges and unlocking new levels of performance.

Selecting the right micro glass fiber product is not a one-size-fits-all decision. It is a nuanced process that demands a deep understanding of your application, manufacturing process, and the specific property enhancements you seek. This guide will provide a detailed framework to help you navigate this selection process, ensuring you choose the optimal product to meet your composite’s unique requirements.

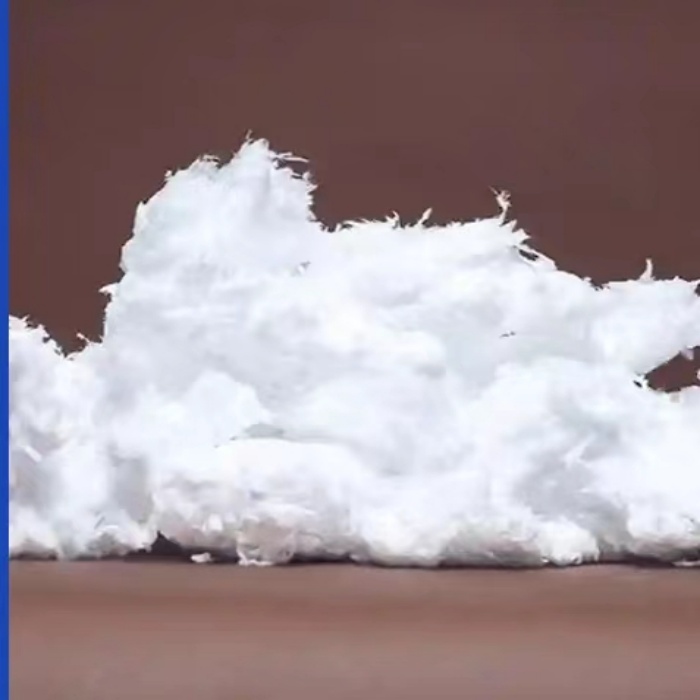

Understanding Micro Glass Fibers: More Than Just Filler

It’s a common misconception to group micro glass fibers with conventional fillers like calcium carbonate or talc. While they can affect cost, their primary function is far more active and transformative.

Micro glass fibers are produced by milling continuous glass filaments or other glass forms into extremely fine, fibrous particles. Their high aspect ratio (length-to-diameter ratio) and chemically inert, yet compatible, silicate-based structure give them unique capabilities:

- Reinforcement: They form a dense, intricate micro-reinforcement network within the composite, significantly enhancing mechanical properties such as tensile strength, flexural modulus, and impact resistance.

- Crack Control: They effectively inhibit crack propagation under stress, increasing the durability and fatigue resistance of the material.

- Dimensional Stability: They dramatically reduce shrinkage and warpage during the curing and cooling processes, which is critical for maintaining tight tolerances.

- Thixotropy and Viscosity Control: They are excellent rheology modifiers, preventing sagging or drainage in vertical applications and resin runoff in open molds, while still allowing the material to flow easily under shear force during processing.

Key Factors to Consider When Choosing a Micro Glass Fiber

The choice hinges on a careful evaluation of several interconnected factors. The optimal product is the one that best balances these parameters for your specific scenario.

1. Fiber Diameter and Length (Aspect Ratio)

This is the most critical technical consideration. Micro glass fibers are typically categorized by their nominal diameter, measured in microns (µm).

- Standard Microfibers (e.g., 10-16 µm): These offer a excellent balance of reinforcement, viscosity control, and surface quality. They are a versatile choice for a wide range of general applications like SMC/BMC, casting, and polymer compounding.

- Fine Microfibers (e.g., 6-9 µm): Finer diameters mean more fibers per unit weight, creating a denser reinforcement network. This leads to superior mechanical properties, better crack resistance, and a smoother surface finish. They are ideal for high-performance applications but can lead to higher viscosity.

- Ultra-Fine Microfibers (e.g., < 5 µm): These provide the highest level of micro-reinforcement and surface perfection. They are often used in highly specialized applications, such as aerospace components, precision electronic substrates, and thin films where minimal surface profile is paramount.

The aspect ratio (length/diameter) is directly linked to reinforcing efficiency. A higher aspect ratio generally translates to better load transfer and stronger mechanical properties. However, it also increases viscosity more significantly.

2. Coupling Agent (Surface Treatment)

The surface of glass fibers is inherently smooth and inorganic, while polymer resins are organic. Without a proper bridge, stress cannot be efficiently transferred from the resin to the fiber, leading to poor performance and potential failure at the interface.

Coupling agents are essential. The most common and effective coupling agent for glass fibers is aminosilane. It acts as a chemical handshake: one end of the molecule bonds with the silicon on the glass surface, while the organic amine end reacts with or entangles within the polymer matrix (especially epoxy, polyurethane, and nylon).

When selecting a product, ensure it is pre-treated with a coupling agent compatible with your resin system:

- Epoxy, PU, Nylon: Aminosilane is standard.

- Polyester/Vinyl Ester: May use aminosilane or other specialized agents.

- PP, PE: Polypropylene-compatible formulations (often with a proprietary coating) are required for optimal dispersion and performance in thermoplastics.

3. Resin System and Manufacturing Process

Your choice of matrix and how you process it will heavily influence the best micro fiber type.

- Thermosets (Epoxy, Polyester, Vinyl Ester, Polyurethane): Micro fibers are widely used in thermoset processes like:Thermoplastics (Nylon, PP, PBT, etc.): Incorporated during compounding, micro fibers boost stiffness, heat deflection temperature (HDT), and dimensional stability of injection-molded or extruded parts. Dispersion is key to avoid fiber agglomeration.

- SMC/BMC: For low-shrink, high-strength, Class A surface parts. Fiber choice is crucial for mold flow and surface finish.

- Pultrusion: To enhance surface quality and longitudinal stiffness.

- Lay-up/Spray-up: To add thixotropy, preventing resin drainage on vertical surfaces.

- Casting & Potting: For crack resistance and reduced exothermic heat in thick sections.

The process dictates the viscosity window. A high-speed injection molding machine can handle a higher-load, higher-viscosity compound than a hand lay-up process where easy brushability is required.

4. Desired Property Enhancements

Clearly define your primary goal. Is it?

- Maximum Strength/Stiffness: Prioritize finer diameters and higher aspect ratio fibers.

- Minimal Shrinkage/Warpage: Most micro fibers excel here; standard grades are often sufficient.

- Superior Surface Finish: Mandates the use of fine or ultra-fine fibers.

- Crack Resistance: Fine fibers with a high aspect ratio create a more effective barrier to crack propagation.

- Thixotropy: Standard grades are very effective for building viscosity and anti-sag properties.

5. Handling and Health & Safety

Micro glass fibers are a respirable dust. While not classified as a carcinogen like crystalline silica, inhalation should be avoided as it can cause mechanical irritation.

- Dust-Control Formats: The industry has moved decisively towards low-dusting and dust-suppressed (DS) products. These are coated with a harmless processing aid (often a polyol) that binds the fibers together, dramatically reducing airborne dust during handling and mixing. This is a critical consideration for operator safety and factory cleanliness.

- Processability: Dust-suppressed products also tend to wet-out faster and incorporate into resins more easily, reducing mixing time and entrapped air.

Always consult the product’s Safety Data Sheet (SDS) and employ appropriate engineering controls (ventilation) and personal protective equipment (PPE) like respirators (NIOSH N95 or better) and gloves.

A Practical Selection Workflow

- Define Requirements: List the top 3-5 required property improvements (e.g., reduce warpage by 80%, improve HDT by 20°C, achieve a smooth surface finish).

- Identify Constraints: Determine your processing method and the maximum viscosity your process can tolerate. Establish your target loading level (often 5-15% by weight).

- Narrow by Resin Compatibility: Only consider fibers pre-treated with a coupling agent for your resin (e.g., aminosilane for epoxy).

- Choose Diameter Grade:

- For all-around performance: Start with a standard 13µm product.

- For high surface finish and maximum strength: Specify a fine 6µm product.

- For extreme surface needs and ultra-high reinforcement: Explore ultra-fine (<5µm) products.

- Prioritize Safety and Handling: Always choose a dust-suppressed (DS) format unless you have a closed, automated system that justifies a non-DS product. This is a non-negotiable best practice for modern manufacturing.

- Test and Validate: Laboratory-scale testing is essential. Create small batches with 2-3 shortlisted products and test for your key metrics: viscosity, mechanical properties, shrinkage, and surface quality.

Conclusion: An Investment in Performance

Choosing the right micro glass fiber is a strategic decision that directly impacts the performance, quality, and manufacturability of your composite material. By moving beyond the concept of a simple filler and understanding the critical roles of fiber diameter, coupling chemistry, and format, you can make an informed choice.

Post time: Sep-04-2025