Manufacturer for Silicone Straw Bulk - Pla Resin Applicable To Extrusion Process – FANCYCO Detail:

Biomaterials PLA polymer REVODE110 is a thermoplastic resin derived from annually renewable resources and is Applicable to extrusion process.

Resin Properties

| REVODE110 | Test Method | |

| Physical Properties | ||

| Density(g/cm3) | 1.25±0.05 | GB/T1033-1986 |

| Melt Index, g/10min (190℃/2.16kg) | 4.0-5.5 | GB/T3682-2000 |

| Melting Point (℃) | 155-160 | GB/T19466.3-2004 |

| Glass Transition Temperature (℃) | 56-60 | GB/T19466.2-2004 |

| Mechanical Properties | ||

| Tensile Strength (MPa) ≥ | 50 | GB/T1040-1992 |

| Elongation at Break (%)≥ | 3.0 | GB/T1040-1992 |

| Impact Strength (KJ/m2, Izod) | 1-3 | GB/T1043-1992 |

Applications:

Many products can be produced from REVODE110, and the application field of this resin is extended gradually. Suitable products including: 3D printing consumables, consumables, modified, transparent sheet, blister tray, bubble shell, IC card, earthwork and so on.

Process Details

Equipment requirements

REVODE110 is suitable for machining in traditional extrusion type wire drawing machines A sheet thickness between 10-20 mm is recommended. General equipment requirements are: screw with L/D ratio between 28:1 to 32:1 and smooth stuff barrel. Stuff is stable in melt form given it is properly dried.

Cleaning machine

PLA resin REVODE110 is different from other resins, and special purging sequences should be followed:

- Clean extruder and bring temperatures to steady state with low-viscosity, general-purpose polystyrene or polypropylene.

- Contamination of hopper system should be avoid, and the humidity of the air should be kept below -40℃ air dew point.

- PLA resin can be introduced into extruder after step 1 and 2.

- Adjust the temperature of equipment to the operating condition.

- When shutting down, the machine should be cleaned with low-viscosity polystyrene or polypropylene.

- Contamination of hopper system should be avoid, and the humidity of the air should be kept below -40℃ air dew point.

Note:

- It is critical that all drying and conveying/receiving systems should be free of all

other contaminant and is vacuumed to ensure that there is no remaining other polymer dust before adding PLA. Since the presence of other polymer contaminant that cannot melt at PLA operating temperature will block screens.

- When cleaning extruder with polypropylene, the thermally cross-linked one should be avoid.

Drying

REVODE110 has been processed by drying crystallization at our factory. Highest heat stability of the resin is 110 ℃ and the moisture content is less than 200 ppm. The resin is stored in Aluminum foil bag, protected by box or bag as the outer packaging, and can be used directly. It is more favorable if resin user can re-dry the resin with proper drying equipment and lower the moisture content to 100 ppm or less. It will enhance the processability of the resin and the quality of the consumables

When re-drying the resin, un-dehumidified hot air is forbidden (by using un- dehumidified air, it will speed up water absorption of PLA resin and cause degradation on the resin). Only dehumidified air can guarantee good drying effect of PLA resin in desiccator.

Recommended drying conditions are as follows:

| Drying Parameter | Typical Settings |

| Residence Time(hours) | 2-3 |

| Air Temperature(℃) | 80 |

| Air Dew Point(℃) | -(40~ 42) |

| Air Flow Rate(m3/hr-kg resin) | >1.85 |

Process temperature

Typical PLA solid line processing parameters:

| Extrusion Area | Temperature Setting(℃) |

| Feed Throat | 130-150 |

| Zone 1 | 175-190 |

| Zone 2 | 175-190 |

| Zone 3 | 175-190 |

| Die | 170-185 |

Note: 1. Temperature settings can be optimized during the production process.

- If the feeding area is blocked, the temperature can be reduced to 110~130 degrees, and the cooling water cycle should be opened.

- Because there are many kinds of extruder on the market, the actual processing temperature will be different for different screw design. Recovery treatment of renewable materials

REVODE110 renewable materials can be recycled, waste material in the extrusion drawing collection centralized processing, after granulator particles can be used as machine cleaning materials, reduce production costs.

infrared and stired by rotation mixer after being added into the infrared crystallization rolling barrel. The merit of this method is that the crystallization and drying process can be carried out simultaneously and the process can be finished within 15~20 min.

Crystallization method 3:

After being pre-dried at low-temperature, the renewable materials is then extruded and palletized, after that, the crystallization process can be carried on in PET crystallization equipment.

Note: Bits and pieces can be reused for several times. During the reuse process, a small amount of assistant agent – ADR can be added to reduce property deterioration of the renewable materials effectively, and the recommended amount is 0.1~0.6%.

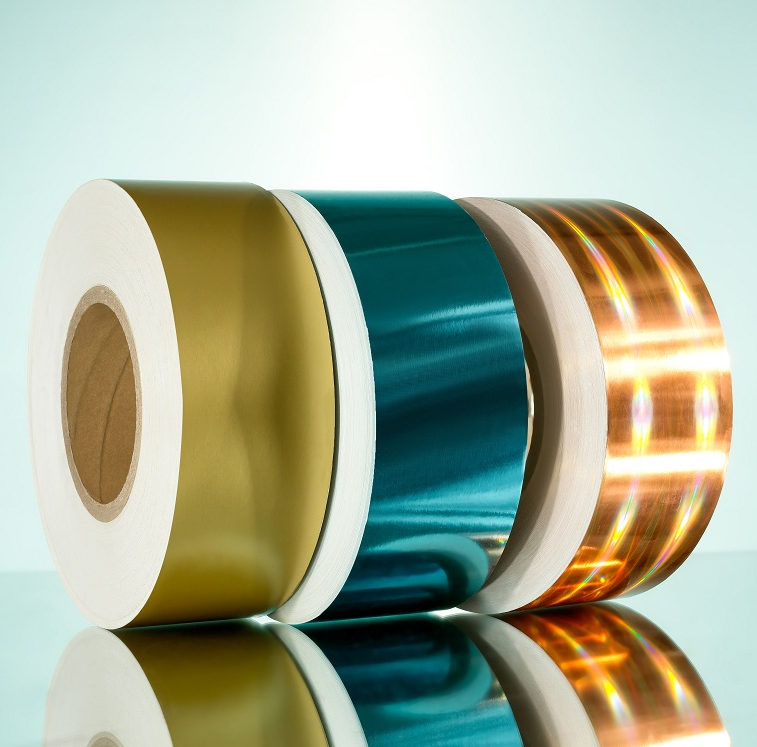

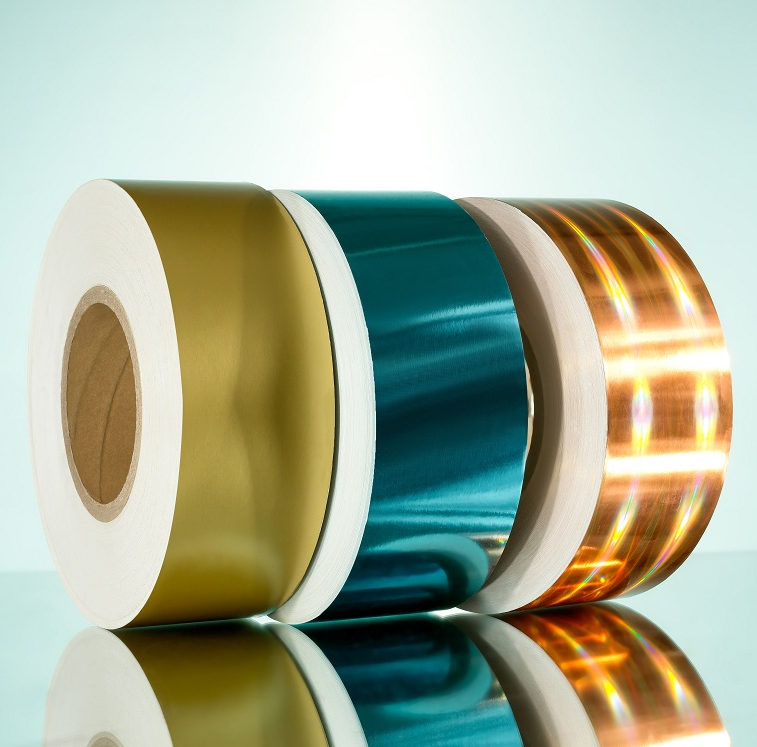

Product detail pictures:

Related Product Guide:

Global Patrol Boats Market Insights 2018-2024: Fassmer, Maritime Partner AS, SAFE Boats, FB Design, Sunbird Yacht, Marine Alutech, BCGP | Easy Tear Vinyl Duct Tape

‘Tripping balls’ makes first appearance in police report for naked woman’s arrest | Opp Tape Slitting Rewinding Machine

Being supported by an state-of-the-art and skilled IT team, we could supply technical support on pre-sales & after-sales service for Manufacturer for Silicone Straw Bulk - Pla Resin Applicable To Extrusion Process – FANCYCO, The product will supply to all over the world, such as: Seychelles, Bolivia, Milan, We strongly believe that technology and service is our base today and quality will create our reliable walls of future. Only we have better and better quality , could we achieve our customers and ourselves, too. Welcome customers all over the word to contact us for getting further business and reliable relationships. We are always here working for your demands whenever you need.

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!

-

Professional Design Food Packing Household Alum...

-

China Manufacturer for Self Adhesive Aluminum F...

-

Discount Price Gift Boxes For Clothes - paper ...

-

OEM China Foil Rose Gold Paper Drinking Straws ...

-

China Gold Supplier for Plastic Disposable Drin...

-

2017 China New Design Decorative Paper Straws -...